.jpg)

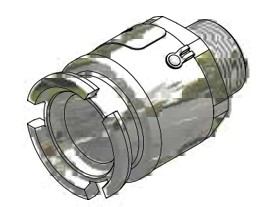

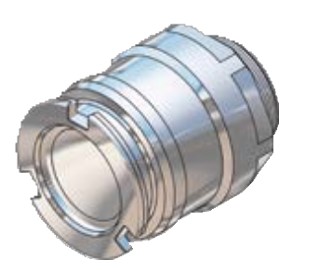

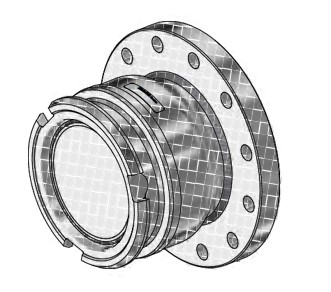

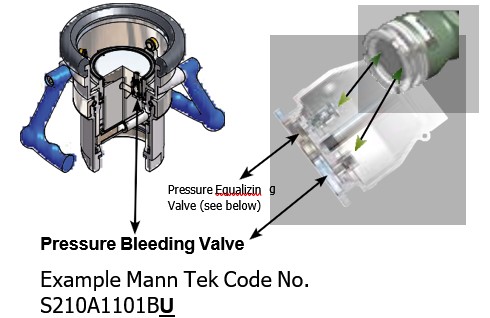

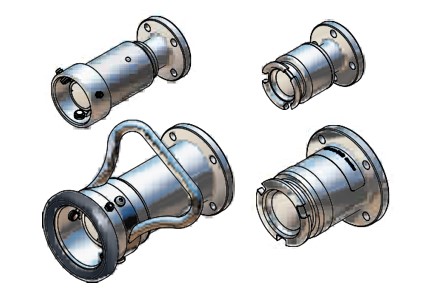

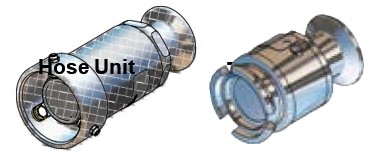

Dry Disconnect Couplings

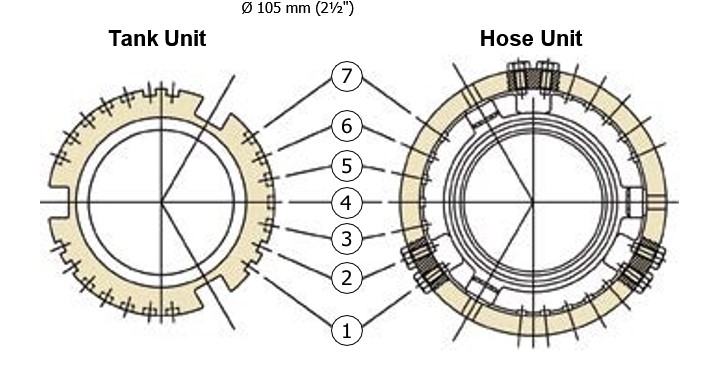

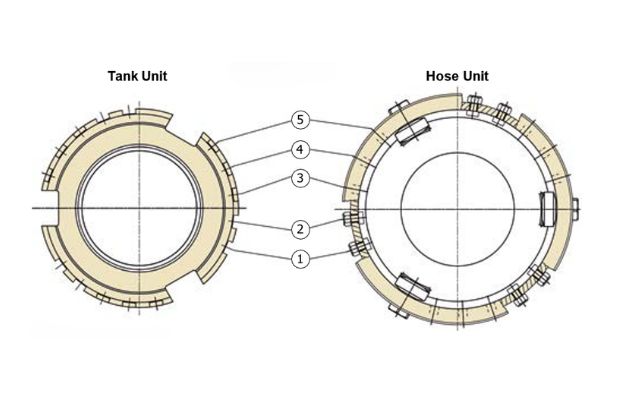

Tank Unit (Adapter) and Hose Unit (Coupler)

|

Material |

Maximum Working Pressure |

Test Pressure |

Minimum Burst Pressure |

|

Aluminium |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Brass / Gunmetal |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Stainless Steel |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Titan |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Hastelloy |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

PEEK |

6 bar / 87 psi |

9 bar / 131 psi |

30 bar / 435 psi |

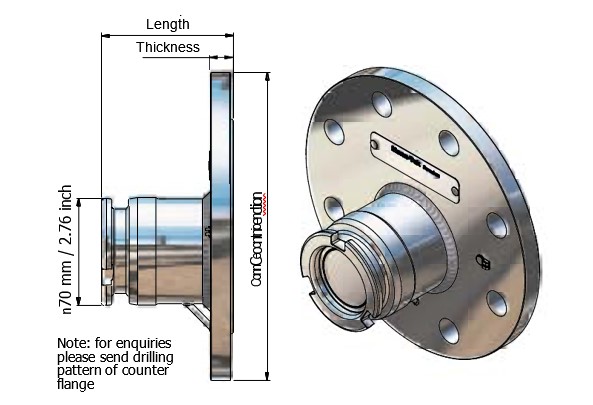

¾", 1" and 1¼" in BSP, NPT or metrical thread, or flanged inlet.

For industrial process plant, road and rail tankers, IBC containers, pharmaceutical and petrochemical industries, diesel locomotive refuelling etc. Recommended for all types of mini bulk liquid product transfer, including container and drum filling, or on any application where spillage needs to be minimized.

Petroleum products: gasoline, diesel, oil etc.

Chemical products: e. g. ethylene oxide, propylene oxide, acrylonitrile, butadiene, ammonia, vinyl chloride, toluene, xylene, sulphuric acid, phenol etc.

Gas: vapor recovery/balance systems for various media.

Aluminium, brass, stainless steel, Hastelloy and PEEK. Others on request.

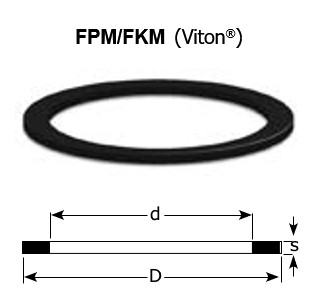

Standard seals in FPM (Viton®) - alternatively EPDM, FKM (Chemraz®, Kalrez®), NBR/HBNR. Other materials on request.

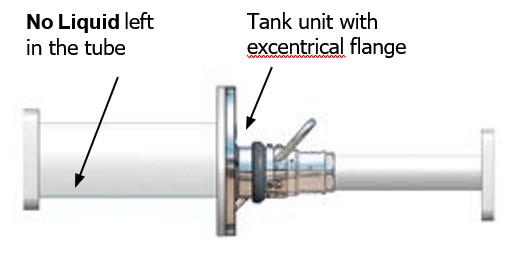

Allows maximum product transfer with minimal losses.

200 litres / minute (fuel).

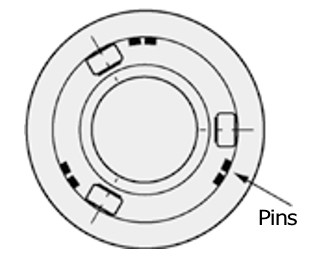

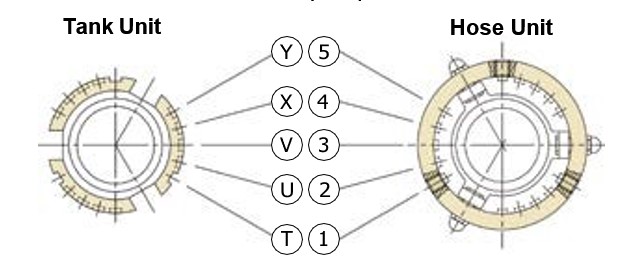

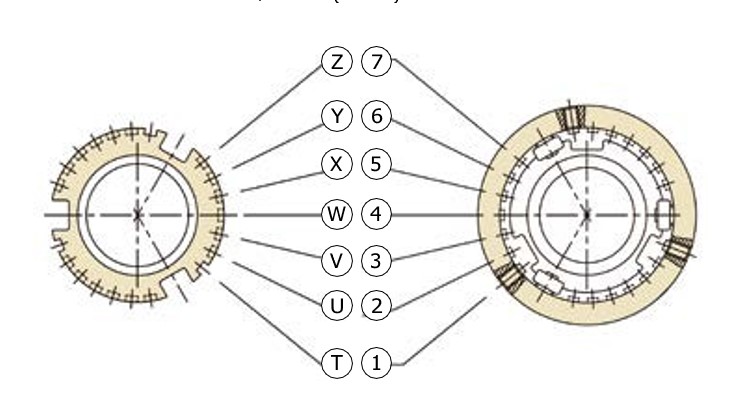

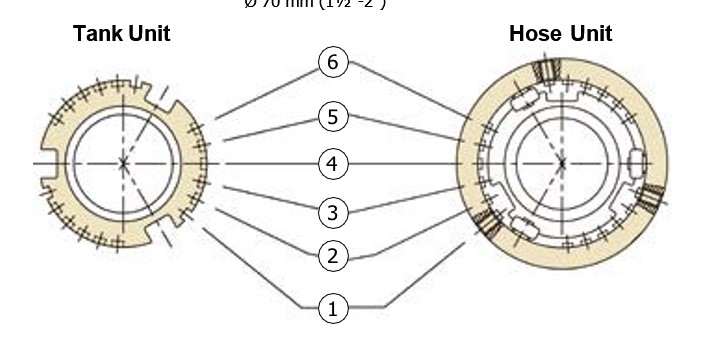

To avoid product contamination caused by connecting a hose unit to the wrong tank unit, selective versions of the hose and tank units are available. Each unit has a number of selective positions, designated by a coded part number according to the coupling size, specify when placing order. See page 32 ff.

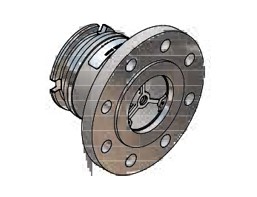

Compatible with couplings of other manufacturers.

All hose units are supplied with an integrated swivel.

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Flat Seal |

kg |

lbs |

|||

|

F ½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

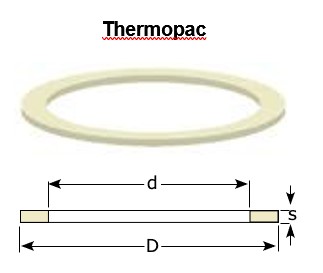

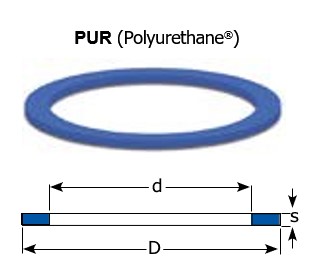

PUR (Polyurethane) |

0,3 |

0.7 |

T1133A1101B |

|

F ¾" BSP |

T101A1101B |

|||||

|

F 1" BSP |

T103A1101B |

|||||

|

F 1¼" BSP |

T105A1101B |

|||||

|

F M 54 x 1,5 |

T1138A1101B |

|||||

|

F ½" NPT |

— |

T1132A1101 |

||||

|

F ¾" NPT |

T102A1101 |

|||||

|

F 1" NPT |

T104A1101 |

|||||

|

F 1¼" NPT |

T106A1101 |

|||||

|

F ½" BSP |

Br |

PUR (Polyurethane) |

0,7 |

1.5 |

T1133A2201B |

|

|

F ¾" BSP |

T101A2201B |

|||||

|

F 1" BSP |

T103A2201B |

|||||

|

F 1¼" BSP |

T105A2201B |

|||||

|

F M 54 x 1,5 |

T1138A2201B |

|||||

|

F ½" NPT |

— |

T1132A2201 |

||||

|

F ¾" NPT |

T102A2201 |

|||||

|

F 1" NPT |

T104A2201 |

|||||

|

F 1¼" NPT |

T106A2201 |

|||||

|

F ½" BSP |

SS |

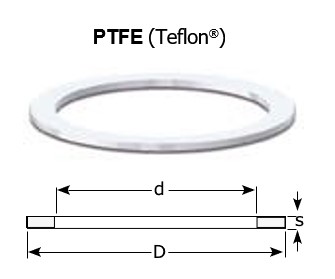

PTFE (Teflon®) |

0,7 |

1.5 |

T1133A4401B |

|

|

F ¾" BSP |

T101A4401A |

|||||

|

F 1" BSP |

T103A4401A |

|||||

|

F 1¼" BSP |

T105A4401A |

|||||

|

F M 54 x 1,5 |

T1138A4401A |

|||||

|

F ½" NPT |

— |

T1132A4401 |

||||

|

F ¾" NPT |

T102A4401 |

|||||

|

F 1" NPT |

T104A4401 |

|||||

|

F 1¼" NPT |

T106A4401 |

|||||

|

F ¾" BSP |

Titan |

PTFE (Teflon®) |

0,4 |

0.9 |

T101A6601A |

|

|

F 1" BSP |

T103A6601A |

|||||

|

F 1¼" BSP |

T105A6601A |

|||||

|

F ¾" NPT |

— |

T102A6601 |

||||

|

F 1" NPT |

T104A6601 |

|||||

|

F 1¼" NPT |

T106A6601 |

|||||

|

F ¾" BSP |

Hastelloy |

PTFE (Teflon®) |

0,8 |

1.8 |

T101A7701A |

|

|

F 1" BSP |

T103A7701A |

|||||

|

F 1¼" BSP |

T105A7701A |

|||||

|

F ¾" NPT |

— |

T102A7701 |

||||

|

F 1" NPT |

T104A7701 |

|||||

|

F 1¼" NPT |

T106A7701 |

|||||

|

F ¾" BSP |

PEEK |

PTFE (Teflon®) |

0,1 |

0.2 |

T101A9901A |

|

|

F 1" BSP |

T103A9901A |

|||||

|

F 1¼" BSP |

T105A9901A |

|||||

|

F ¾" NPT |

— |

T102A9901 |

||||

|

F 1" NPT |

T104A9901 |

|||||

|

F 1¼" NPT |

T106A9901 |

|||||

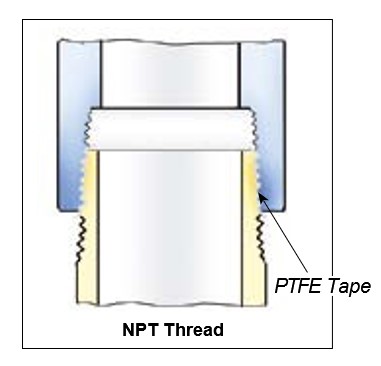

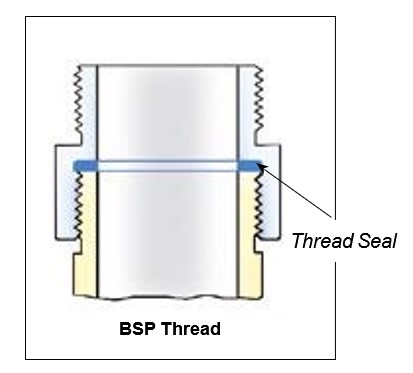

1) F = Female thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® and Teflon® are registred trademarks of DuPont, DuPont Elastomers.

|

Connection 1) Inch/DN |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

M ¾" BSP |

|

|

|

|

T169A1101 |

|

|

M ¾" NPT |

Al |

|

T170A1101 |

|||

|

M 1" BSP |

T171A1101 |

|||||

|

M 1" NPT |

|

Standard: |

T172A1101 |

|||

|

M ¾" BSP |

|

|

|

T169A1101 |

||

|

|

FPM/FKM |

|||||

|

M ¾" NPT |

T170A1101 |

|||||

|

Br |

(Viton®)

Other on |

|||||

|

M 1" BSP |

T171A1101 |

|||||

|

M 1" NPT |

T172A1101 |

|||||

|

|

request. |

|||||

|

M ¾" BSP |

|

|

|

T169A4401 |

||

|

M ¾" NPT |

SS |

|

T170A4401 |

|||

|

M 1" BSP |

T171A4401 |

|||||

|

M 1" NPT |

|

|

T172A4401 |

|||

1) M = Male thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel,

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

|

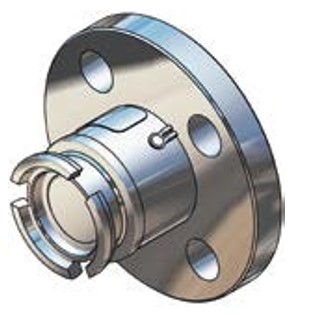

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

undrilled |

|

|

|

|

T118A1101 |

|

|

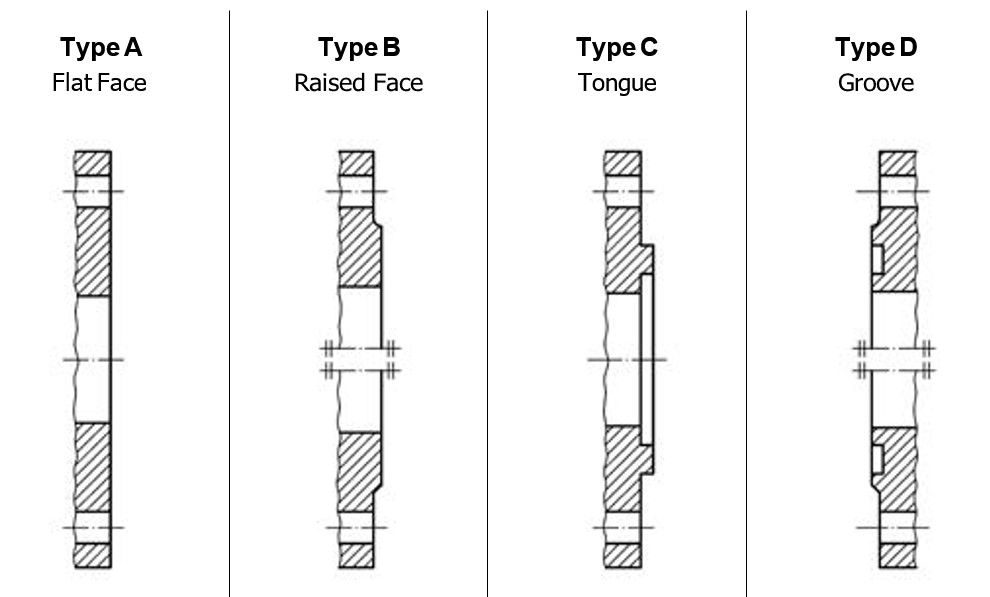

DN 25 PN 10 / 16 Type A |

|

|

|

|

T123A1101 |

|

|

DN 25 PN 25 / 40 Type A |

Al |

|

1,1 |

2.4 |

T124A1101 |

|

|

1" ASA 150 |

|

|

|

|

T151A1101 |

|

|

1" ASA 300 |

|

|

|

|

T152A1101 |

|

|

undrilled |

|

|

|

T118A2201 |

||

|

DN 25 PN 10 / 16 Type B |

|

|

|

|

T123A2201 |

|

|

DN 25 PN 25 / 40 Type B |

Br |

|

1,6 |

3.5 |

T124A2201 |

|

|

1" ASA 150 |

|

|

|

|

T151A2201 |

|

|

1" ASA 300 |

|

|

|

|

T152A2201 |

|

|

undrilled |

|

1,5 |

3.3 |

T118A4401 |

||

|

DN 25 PN 10 / 16 Type B |

|

|

T123A4401 |

|||

|

DN 25 PN 25 / 40 Type B |

SS |

Standard: |

T124A4401 |

|||

|

|

FPM/FKM |

|||||

|

1" ASA 150 |

T151A4401 |

|||||

|

|

(Viton®) |

|||||

|

1" ASA 300 |

T152A4401 |

|||||

|

undrilled |

|

Other on |

|

|

T118A6601 |

|

|

DN 25 PN 10 / 16 Type B |

T123A6601 |

|||||

|

|

request. |

|

|

|||

|

DN 25 PN 25 / 40 Type B |

Titan |

|

0,8 |

1.8 |

T124A6601 |

|

|

1" ASA 150 |

|

|

|

|

T151A6601 |

|

|

1" ASA 300 |

|

|

|

|

T152A6601 |

|

|

DN 25 PN 10 / 16 Type B |

|

|

|

T123A7701 |

||

|

DN 25 PN 25 / 40 Type B |

Hastelloy |

|

1,7 |

3.8 |

T124A7701 |

|

|

1" ASA 150 |

T151A7701 |

|||||

|

1" ASA 300 |

|

|

|

|

T152A7701 |

|

|

undrilled |

|

|

|

T118A9901 |

||

|

DN 25 PN 10 / 16 Type B |

|

|

|

|

T123A9901 |

|

|

DN 25 PN 25 / 40 Type B |

PEEK |

|

0,2 |

0.4 |

T124A9901 |

|

|

1" ASA 150 |

|

|

|

|

T151A9901 |

|

|

1" ASA 300 |

|

|

|

|

T152A9901 |

|

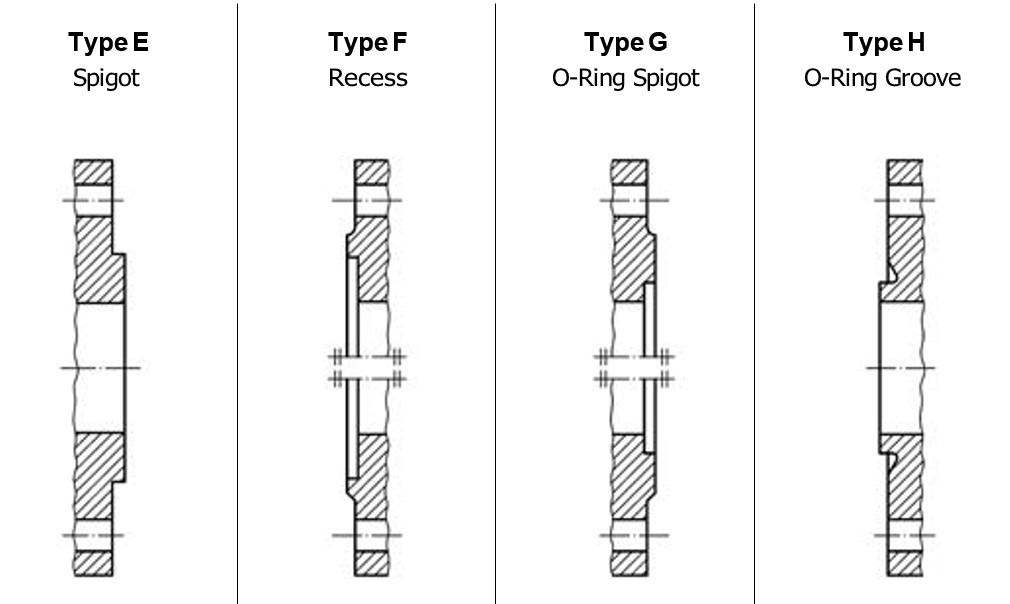

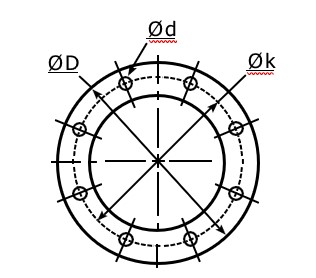

1) PN 10 / 16 / 25 / 40 = EN 1092 (types see page 44), ANSI B16.5.

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® is a registred trademark of DuPont, DuPont Elastomers.

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F ½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

0,5 |

1.1 |

S1133A1101B |

|

F ¾" BSP |

S101A1101B |

|||||

|

F 1" BSP |

S103A1101B |

|||||

|

F 1¼" BSP |

S105A1101B |

|||||

|

F M 54 x 1,5 |

S1138A1101B |

|||||

|

F ½" NPT |

— |

S1132A1101 |

||||

|

F ¾" NPT |

S102A1101 |

|||||

|

F 1" NPT |

S104A1101 |

|||||

|

F 1¼" NPT |

S106A1101 |

|||||

|

F ½" BSP |

Br |

PUR (Polyurethane) |

1,4 |

3.1 |

S1133A2201B |

|

|

F ¾" BSP |

S101A2201B |

|||||

|

F 1" BSP |

S103A2201B |

|||||

|

F 1¼" BSP |

S105A2201B |

|||||

|

F M 54 x 1,5 |

S1138A2201B |

|||||

|

F ½" NPT |

— |

S1132A2201 |

||||

|

F ¾" NPT |

S102A2201 |

|||||

|

F 1" NPT |

S104A2201 |

|||||

|

F 1¼" NPT |

S106A2201 |

|||||

|

F ½" BSP |

SS |

PTFE (Teflon®) |

1,3 |

2.9 |

S1133A4401A |

|

|

F ¾" BSP |

S101A4401A |

|||||

|

F 1" BSP |

S103A4401A |

|||||

|

F 1¼" BSP |

S105A4401A |

|||||

|

F M 54 x 1,5 |

S1138A4401A |

|||||

|

F ½" NPT |

— |

S1132A4401 |

||||

|

F ¾" NPT |

S102A4401 |

|||||

|

F 1" NPT |

S104A4401 |

|||||

|

F 1¼" NPT |

S106A4401 |

|||||

|

F ¾" BSP |

Titan |

PTFE (Teflon®) |

0,7 |

1.5 |

S101A6601A |

|

|

F 1" BSP |

S103A6601A |

|||||

|

F 1¼" BSP |

S105A6601A |

|||||

|

F ¾" NPT |

— |

S102A6601 |

||||

|

F 1" NPT |

S104A6601 |

|||||

|

F 1¼" NPT |

S106A6601 |

|||||

|

F ¾" BSP |

Hastelloy |

PTFE (Teflon®) |

1,5 |

3.3 |

S101A7701A |

|

|

F 1" BSP |

S103A7701A |

|||||

|

F 1¼" BSP |

S105A7701A |

|||||

|

F ¾" NPT |

— |

S102A7701 |

||||

|

F 1" NPT |

S104A7701 |

|||||

|

F 1¼" NPT |

S106A7701 |

|||||

|

F ¾" BSP |

PEEK |

PTFE (Teflon®) |

0,3 |

0.7 |

S101A9901A |

|

|

F 1" BSP |

S103A9901A |

|||||

|

F 1¼" BSP |

S105A9901A |

|||||

|

F ¾" NPT |

— |

S102A9901 |

||||

|

F 1" NPT |

S104A9901 |

|||||

|

F 1¼" NPT |

S106A9901 |

|||||

1) F = Female thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® and Teflon® are registred trademarks of DuPont, DuPont Elastomers.

|

Connection 1) Inch/DN |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

M ¾" BSP |

|

|

|

|

S169A1101 |

|

|

M ¾" NPT |

Al |

|

S170A1101 |

|||

|

M 1" BSP |

S171A1101 |

|||||

|

M 1" NPT |

|

Standard: |

S172A1101 |

|||

|

M ¾" BSP |

|

|

|

S169A1101 |

||

|

|

FPM/FKM |

|||||

|

M ¾" NPT |

S170A1101 |

|||||

|

Br |

(Viton®)

Other on |

|||||

|

M 1" BSP |

S171A1101 |

|||||

|

M 1" NPT |

S172A1101 |

|||||

|

|

request. |

|||||

|

M ¾" BSP |

|

|

|

S169A4401 |

||

|

M ¾" NPT |

SS |

|

|

|

S170A4401 |

|

|

M 1" BSP |

|

|

S171A4401 |

|||

|

M 1" NPT |

|

|

1,4 |

3.0 |

S172A4401 |

|

1) M = Male thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials,

e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

1,1 |

2.4 |

S118A1101 |

|

DN 25 PN 10 / 16 Type A |

S123A1101 |

||||

|

DN 25 PN 25 / 40 Type A |

S124A1101 |

||||

|

¾" ASA 150 |

S149A1101 |

||||

|

1" ASA 150 |

S151A1101 |

||||

|

1" ASA 300 |

S152A1101 |

||||

|

DN 25 DIN 11864 |

S1151A1101 |

||||

|

undrilled |

Br |

1,6 |

3.5 |

S118A2201 |

|

|

DN 25 PN 10 / 16 Type B |

S123A2201 |

||||

|

DN 25 PN 25 / 40 Type B |

S124A2201 |

||||

|

¾" ASA 150 |

S149A2201 |

||||

|

1" ASA 150 |

S151A2201 |

||||

|

1" ASA 300 |

S152A2201 |

||||

|

undrilled |

SS |

2,2 |

4.9 |

S118A4401 |

|

|

DN 25 PN 10 / 16 Type B |

S123A4401 |

||||

|

DN 25 PN 25 / 40 Type B |

S124A4401 |

||||

|

¾" ASA 150 |

S149A4401 |

||||

|

1" ASA 150 |

S151A4401 |

||||

|

1" ASA 300 |

S152A4401 |

||||

|

undrilled |

Titan |

1,2 |

2.7 |

S118A6601 |

|

|

DN 25 PN 10 / 16 Type B |

S123A6601 |

||||

|

DN 25 PN 25 / 40 Type B |

S124A6601 |

||||

|

1" ASA 150 |

S151A6601 |

||||

|

1" ASA 300 |

S152A6601 |

||||

|

DN 25 PN 10 / 16 Type B |

Hastelloy |

2,5 |

5.5 |

S123A7701 |

|

|

DN 25 PN 25 / 40 Type B |

S124A7701 |

||||

|

1" ASA 150 |

S151A7701 |

||||

|

1" ASA 300 |

S152A7701 |

||||

|

undrilled |

PEEK |

0,5 |

1.1 |

S118A9901 |

|

|

DN 25 PN 10 / 16 Type B |

S123A9901 |

||||

|

DN 25 PN 25 / 40 Type B |

S124A9901 |

||||

|

1" ASA 150 |

S151A9901 |

||||

|

1" ASA 300 |

S152A9901 |

||||

1) PN 10 / 16 / 25 / 40 = EN 1092

ASA = ANSI B16.5 (150 o. 300 psi), 150

or 300 psi.

DIN 11864 = DIN 11864-2 (aseptic flange)

2) Material: Al = Aluminium,

Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® is a registred trademark of DuPont, DuPont Elastomers.

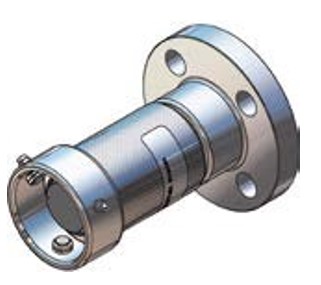

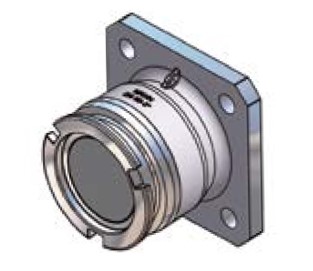

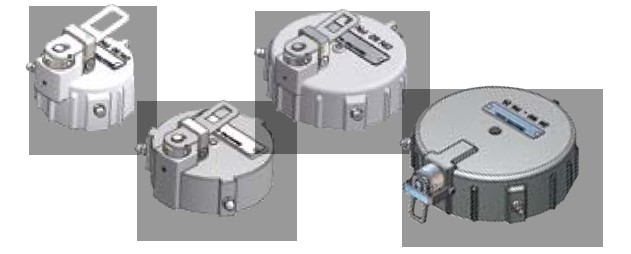

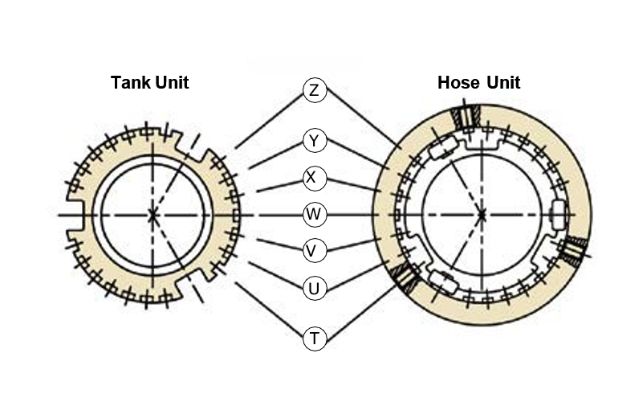

Tank Unit (Adapter) and Hose Unit (Coupler)

|

Material |

Maximum Working Pressure |

Test Pressure |

Minimum Burst Pressure |

|

Aluminium |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Brass / Gunmetal |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Stainless Steel |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Titan |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Hastelloy |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

PEEK |

6 bar / 87 psi |

9 bar / 131 psi |

30 bar / 435 psi |

1½" and 2" in BSP, NPT or S60x6 thread, or flanged inlet.

For industrial process plant, road and rail tankers, ISO tank containers, IBC containers, pharmaceutical and petrochemical industries or on any application where spillage needs to be minimized.

Petroleum products: gasoline, diesel, oil etc. Chemical products: AdBlue, ethylene oxide, propylene oxide, acrylonitrile, butadiene, ammonia, vinyl chloride, toluene, xylene, sulphuric acid, phenol etc.

Gas: vapor recovery/balance systems for for various media.

Dry powder.

Aluminium, brass/gunmetal, stainless steel, Hastelloy and PEEK. Other materials on request.

Standard seals in FPM (Viton®) - alternatively EPDM, FKM (Chemraz®, Kalrez®), NBR/HBNR. Other materials on request.

Allows maximum product transfer with minimal losses.

900 litres/minute (fuel)

To avoid product contamination caused by connecting a hose unit to the wrong tank unit, selective versions of the hose and tank units are available. Each unit has a number of selective positions, desig- nated by a coded part number according to the coup- ling size – specify when placing order. See page 32 ff.

Compatible with couplings of other manufacturers.

All hose units are supplied with an integrated swivel.

According to NATO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F 1½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

0,4 |

0.8 |

T207A1101B |

|

F 2" BSP |

T210A1101B |

|||||

|

F S60x6 |

T2108A1101B |

|||||

|

F W2" - 7 |

T2112A1101B |

|||||

|

F 1½" NPT |

— |

0.4 |

0.8 |

T208A1101 |

||

|

F 2" NPT |

T211A1101 |

|||||

|

F 1½" BSP |

Br |

PUR (Polyurethane) |

1,2 |

2.7 |

T207A2201B |

|

|

F 2" BSP |

1,1 |

2.4 |

T210A2201B |

|||

|

F S 60 x 6 |

1,0 |

2.2 |

T2108A2201B |

|||

|

F W2" - 7 |

1,0 |

0.9 |

T2112A2201B |

|||

|

F 1½" NPT |

— |

0,4 |

0.9 |

T208A2201 |

||

|

F 2" NPT |

1,1 |

2.4 |

T211A2201 |

|||

|

F 1½" BSP |

SS |

PTFE (Teflon®) |

1,1 |

2.4 |

T207A4401A |

|

|

F 2" BSP |

1,0 |

2.2 |

T210A4401A |

|||

|

F S60 x 6 |

1,0 |

2.2 |

T2108A4401A |

|||

|

F 1½" NPT |

— |

1,2 |

2.7 |

T208A4401 |

||

|

F 2" NPT |

1,1 |

2.4 |

T211A4401 |

|||

|

F 1½" BSP |

Titan |

PTFE (Teflon®) |

|

|

T207A6601A |

|

|

F 2" BSP |

0,6 |

1.3 |

T210A6601A |

|||

|

F 1½" NPT |

— |

|

|

T208A6601 |

||

|

F 2" NPT |

0,6 |

1.3 |

T211A6601 |

|||

|

F 1½" BSP |

Hastelloy |

PTFE (Teflon®) |

|

|

T207A7701A |

|

|

F 2" BSP |

|

|

T210A7701A |

|||

|

F 1½" NPT |

— |

|

|

T208A7701 |

||

|

F 2" NPT |

|

|

T211A7701 |

|||

|

F 1½" BSP |

PEEK |

PTFE (Teflon®) |

|

|

T207A9901A |

|

|

F 2" BSP |

0,3 |

0.6 |

T210A9901A |

|||

|

F 1½" NPT |

— |

|

|

T208A9901 |

||

|

F 2" NPT |

0,3 |

0.6 |

T211A9901 |

|||

1) F = Female thread, BSP = EN ISO 228, NPT = ANSI B1.20.1, S60 x 6 = thread for IBC, W 2" heating oil connection Sweden

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

M 2" BSP |

|

|

1,0 |

2.2 |

T278A1101 |

|

|

M 2" NPT |

Al |

Standard: |

|

|

T279A1101 |

|

|

M W2" - 7 |

|

|

T2123A1101 |

|||

|

|

FPM/FKM |

|||||

|

M 2" BSP |

|

|

|

T278A2201 |

||

|

Br |

(Viton®) |

|||||

|

M 2" NPT |

|

|

T279A2201 |

|||

|

M W2" - 7 |

|

Other on |

|

|

T2123A2201 |

|

|

|

request. |

|||||

|

M 2" BSP |

SS |

1,0 |

2.2 |

T278A4401 |

||

|

M 2" NPT |

|

1,1 |

2.4 |

T279A4401 |

||

1) M = Male thread, BSP = EN ISO 228, NPT = ANSI B1.20.1, S 60 x 6 = thread for IBC, W 2" heating oil connection Sweden

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® is a registred trademark of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 165 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

1,0 |

2.2 |

T219B1101 |

|

DN 40 PN 10 / 16 Type A |

0,9 |

2.0 |

T227B1101 |

||

|

1½" ASA 150 |

0,8 |

1.8 |

T255B1101 |

||

|

DN 50 PN 10 / 16 Type A |

1,0 |

2.2 |

T230B1101 |

||

|

2" ASA 150 |

0,9 |

2.0 |

T257B1101 |

||

|

DIN 28459 'TW 1' / DN 80 |

0,9 |

2.0 |

T265B1101 |

||

|

undrilled Ø 165 mm |

GM |

3,3 |

7.3 |

T219B2201 |

|

|

DN 40 PN 10 / 16 Type B |

2,5 |

5.5 |

T227B2201 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

T228B2201 |

||

|

1½" ASA 150 |

2,2 |

4.9 |

T255B2201 |

||

|

1½" ASA 300 |

|

|

T256B2201 |

||

|

DN 50 PN 10 / 16 Type B |

3,1 |

6.8 |

T230B2201 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

T231B2201 |

||

|

2" ASA 150 |

2,5 |

5.1 |

T257B2201 |

||

|

2" ASA 300 |

|

|

T258B2201 |

||

|

DIN 28459 'TW 1' / DN 80 |

2,4 |

5.3 |

T265B2201 |

||

|

undrilled Ø 165 mm |

SS |

3,2 |

7.1 |

T219B4401 |

|

|

undrilled Ø 165 mm **) |

|

|

T219B4401F |

||

|

DN 40 PN 10 / 16 Type B |

2,4 |

5.3 |

T227B4401 |

||

|

DN 40 PN 10 / 16 Type B **) |

|

|

T227B4401F |

||

|

DN 40 PN 25 / 40 Type B |

2,4 |

5.3 |

T228B4401 |

||

|

DN 40 PN 25 / 40 Type B **) |

|

|

T228B4401F |

||

|

1½" ASA 150 |

1,7 |

3.8 |

T255B4401 |

||

|

1½" ASA 150 **) |

|

|

T255B4401F |

||

|

1½" ASA 300 |

2,1 |

4.6 |

T256B4401 |

||

|

1½" ASA 300 **) |

|

|

T256B4401F |

||

|

DN 50 PN 25 / 40 Type E *) |

2,9 |

6.4 |

T229B4401 |

||

|

DN 50 PN 10 / 16 Type B ) |

2,7 |

6.0 |

T230B4401 |

||

|

DN 50 PN 10 / 16 Type B ** |

|

|

T230B4401F |

||

|

DN 50 PN 25 / 40 Type B |

3,0 |

6.6 |

T231B4401 |

||

|

DN 50 PN 25 / 40 Type B **) |

|

|

T231B4401F |

||

|

2" ASA 150 |

2,4 |

5.3 |

T257B4401 |

||

|

2" ASA 150 **) |

|

|

T257B4401F |

||

|

2" ASA 300 |

2,5 |

5.5 |

T258B4401 |

||

|

2" ASA 300 **) |

|

|

T258B4401F |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

T265B4401 |

||

|

DN 50 DIN 11864 |

|

|

T2152B4401 |

||

|

undrilled Ø 165 mm |

Titan |

|

|

T219A6601 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

T227A6601 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

T228A6601 |

||

|

1½" ASA 150 |

1,7 |

3.8 |

T255A6601 |

||

|

1½" ASA 300 |

|

|

T256A6601 |

||

|

DN 50 PN 10 / 16 Type B |

|

|

T230A6601 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

T231A6601 |

||

|

2" ASA 150 |

|

|

T257A6601 |

||

|

2" ASA 300 |

|

|

T258A6601 |

||

|

undrilled Ø 165 mm |

Hastelloy |

|

|

T219A7701 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

T227A7701 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

T228A7701 |

||

|

1½" ASA 150 |

|

|

T255A7701 |

||

|

1½" ASA 300 B |

|

|

T256A7701 |

||

|

DN 50 PN 10 / 16 Type B |

|

|

T230A7701 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

T231A7701 |

||

|

2" ASA 150 |

|

|

T257A7701 |

||

|

2" ASA 300 |

|

|

T258A7701 |

||

|

undrilled Ø 165 mm |

PEEK |

|

|

T219A9901 |

|

|

DN 40 PN 10 / 16 Type B |

1,0 |

2.0 |

T227A9901 |

||

|

1½" ASA 150 |

|

|

T255A9901 |

||

|

DN 50 PN 10 / 16 Type B |

1,0 |

2.0 |

T230A9901 |

||

|

2" ASA 150 |

1,0 |

2.0 |

T257A9901 |

||

*) Type E (with spigot), EN 1092-1, see p. 44

**) Flange with standard thickness

1) PN 10 / 16 / 25 / 40 = EN 1092

(types see page 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = old standard TW, 10 bar. DIN 11864 = DIN 11864-2 (aseptic flange)

2) Material: Al = Aluminium,

GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® is a registred trademark of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F 1½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

1,2 |

2.7 |

S207A1101B |

|

F 1½" BSP-B Mouth*) |

|

|

S207A1101BI |

|||

|

F 2" BSP |

1,1 |

2.4 |

S210A1101B |

|||

|

F 2" BSP-B Mouth*) |

1,1 |

2.4 |

S210A1101BI |

|||

|

F 1½" NPT |

— |

1,1 |

2.4 |

S208A1101 |

||

|

F 1½" NPT-B Mouth*) |

|

|

S208A1101I |

|||

|

F 2" NPT |

1,1 |

2.4 |

S211A1101 |

|||

|

F 2" NPT-B Mouth*) |

|

|

S211A1101I |

|||

|

F 1½" BSP |

Br |

PUR (Polyurethane) |

2,6 |

5.7 |

S207A2201B |

|

|

F 1½" BSP-B Mouth*) |

|

|

S207A2201BI |

|||

|

F 2" BSP |

2,4 |

5.3 |

S210A2201B |

|||

|

F 2" BSP-B Mouth*) |

|

|

S210A2201BI |

|||

|

F 1½" NPT |

— |

2,5 |

5.5 |

S208A2201 |

||

|

F 1½" NPT-B Mouth*) |

|

|

S208A2201I |

|||

|

F 2" NPT |

2,5 |

5.5 |

S211A2201 |

|||

|

F 2" NPT-B Mouth*) |

|

|

S211A2201I |

|||

|

F 1½" BSP |

SS |

PTFE (Teflon®) |

2,5 |

5.5 |

S207A4401A |

|

|

F 2" BSP |

2,3 |

5.1 |

S210A4401A |

|||

|

F 1½" NPT |

— |

2,4 |

5.3 |

S208A4401 |

||

|

F 2" NPT |

2,3 |

5.1 |

S211A4401 |

|||

|

F 1½" BSP |

Titan |

PTFE (Teflon®) |

1,3 |

2.9 |

S207A6601A |

|

|

F 2" BSP |

1,3 |

2.9 |

S210A6601A |

|||

|

F 1½" NPT |

— |

|

|

S208A6601 |

||

|

F 2" NPT |

1,4 |

3.1 |

S211A6601 |

|||

|

F 1½" BSP |

Hastelloy |

PTFE (Teflon®) |

2,3 |

5.1 |

S207A7701A |

|

|

F 2" BSP |

2,3 |

5.1 |

S210A7701A |

|||

|

F 1½" NPT |

— |

2,3 |

5.1 |

S208A7701 |

||

|

F 2" NPT |

2,3 |

5.1 |

S211A7701 |

|||

|

F 1½" BSP |

PEEK |

PTFE (Teflon®) |

|

|

S207A9901A |

|

|

F 2" BSP |

1,3 |

2.9 |

S210A9901A |

|||

|

F 1½" NPT |

— |

|

|

S208A9901 |

||

|

F 2" NPT |

1,3 |

2.9 |

S211A9901 |

|||

*) Adopted for older models of Emco Wheaton male couplings

1) F = Female thread, BSP =

EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

2" BSP AG |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

|

|

S278A1101 |

|

2" NPT AG |

|

|

S279A1101 |

||

|

S60 x 6 AG |

|

|

S2109A1101 |

||

|

W2" - 7 AG |

1,3 |

2.1 |

S2123A1101 |

||

|

2" BSP AG |

Br |

|

|

S278A2201 |

|

|

2" NPT AG |

|

|

S279A2201 |

||

|

S60x6 AG |

|

|

S2109A2201 |

||

|

W2" - 7 AG |

|

|

S2123A2201 |

||

|

2" BSP AG |

SS |

2,3 |

5.1 |

S278A4401 |

|

|

2" NPT AG |

|

|

S279A4401 |

||

|

S60x6 AG |

|

|

S2109A4401 |

||

1) M = Male thread, BSP = EN ISO 228, NPT = ANSI B1.20.1, S 60 x 6 = thread for IBC, W 2" heating oil connection Sweden

2) Material: Al = Aluminium, Br = Brass, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® and Teflon® are registred trademarks of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 165 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

|

|

S219A1101 |

|

DN 40 PN 10 / 16 Type A |

|

|

S227A1101 |

||

|

1½" ASA 150 |

|

|

S255A1101 |

||

|

DN 50 PN 10 / 16 Type A |

2,3 |

5.1 |

S230A1101 |

||

|

2" ASA 150 |

|

|

S257A1101 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S265A1101 |

||

|

undrilled Ø 165 mm |

GM |

|

|

S219A2201 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

S227A2201 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

S228A2201 |

||

|

1½" ASA 150 |

5,1 |

11.2 |

S255A2201 |

||

|

1½" ASA 300 |

|

|

S256A2201 |

||

|

DN 50 PN 10 / 16 Type B |

|

|

S230A2201 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

S231A2201 |

||

|

2" ASA 150 |

5,1 |

11.2 |

S257A2201 |

||

|

2" ASA 300 |

|

|

S258A2201 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S265A2201 |

||

|

undrilled Ø 165 mm |

SS |

|

|

S219A4401 |

|

|

o. Bohrungen Ø 165 mm **) |

|

|

S219A4401F |

||

|

DN 40 PN 10 / 16 Type B |

|

|

S227A4401 |

||

|

DN 40 PN 10 / 16 Type B **) |

|

|

S227A4401F |

||

|

DN 40 PN 25 / 40 Type B |

|

|

S228A4401 |

||

|

DN 40 PN 25 / 40 Type B **) |

|

|

S228A4401F |

||

|

1½" ASA 150 |

|

|

S255A4401 |

||

|

1½" ASA 150 **) |

|

|

S255A4401F |

||

|

1½" ASA 300 |

|

|

S256A4401 |

||

|

1½" ASA 300 **) |

6,6 |

14.6 |

S256A4401F |

||

|

DN 50 PN 25 / 40 Type E *) |

|

|

S229A4401 |

||

|

DN 50 PN 10 / 16 Type B |

5,4 |

11.9 |

S230A4401 |

||

|

DN 50 PN 10 / 16 Type B **) |

|

|

S230A4401F |

||

|

DN 50 PN 25 / 40 Type B |

5,4 |

11.9 |

S231A4401 |

||

|

DN 50 PN 25 / 40 Type B **) |

|

|

S231A4401F |

||

|

2" ASA 150 |

5,1 |

11.2 |

S257A4401 |

||

|

2" ASA 150 **) |

5,1 |

11.2 |

S257A4401F |

||

|

2" ASA 300 |

|

|

S258A4401 |

||

|

2" ASA 300 **) |

2,5 |

5.5 |

S258A4401F |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S265A4401 |

||

|

DN 50 DIN 11864 |

3,1 |

6.8 |

S2152B4401 |

||

|

undrilled Ø 165 mm |

Titan |

|

|

S219A6601 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

S227A6601 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

S228A6601 |

||

|

1½" ASA 150 |

|

|

S255A6601 |

||

|

1½" ASA 300 |

|

|

S256A6601 |

||

|

DN 50 PN 10 / 16 Type B |

|

|

S230A6601 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

S231A6601 |

||

|

2" ASA 150 |

|

|

S257A6601 |

||

|

2" ASA 300 |

|

|

S258A6601 |

||

|

undrilled Ø 165 mm |

Hastelloy |

|

|

S219A7701 |

|

|

DN 40 PN 10 / 16 Type B |

|

|

S227A7701 |

||

|

DN 40 PN 25 / 40 Type B |

|

|

S228A7701 |

||

|

1½" ASA 150 |

|

|

S255A7701 |

||

|

1½" ASA 300 |

|

|

S256A7701 |

||

|

DN 50 PN 10 / 16 Type B |

5,4 |

11.9 |

S230A7701 |

||

|

DN 50 PN 25 / 40 Type B |

|

|

S231A7701 |

||

|

2" ASA 150 |

|

|

S257A7701 |

||

|

2" ASA 300 |

|

|

S258A7701 |

||

|

undrilled Ø 165 mm |

PEEK |

|

|

S219A9901 |

|

|

DN 40 PN 10 / 16 Type B |

5,4 |

11.9 |

S227A9901 |

||

|

1½" ASA 150 Type B |

|

|

S255A9901 |

||

|

DN 50 PN 10 / 16 Type B |

5,4 |

11.9 |

S230A9901 |

||

|

2" ASA 150 |

|

|

S257A9901 |

||

*) Type E (with spigot),

EN 1092-1, see page 44

**) Flange with standard thickness

1) PN 10 / 16 / 25 / 40 = EN 1092

(types see page 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = old standard TW, 10 bar. DIN 11864 = DIN 11864-2 (aseptic flange).

2) Material: Al = Aluminium,

GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® is a registred trademark of DuPont, DuPont Elastomers.

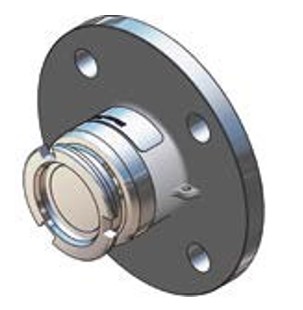

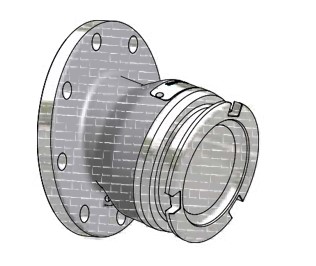

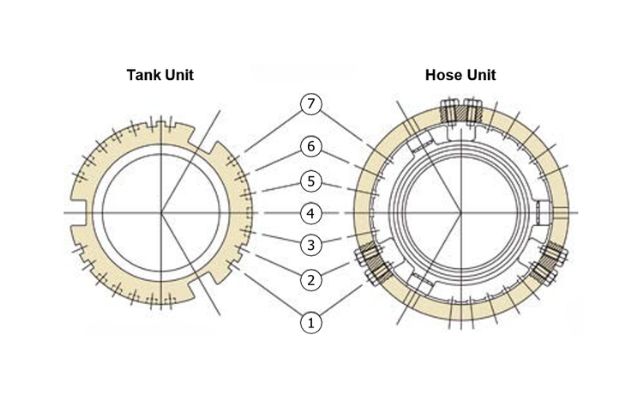

Tank Unit (Adapter) and Hose Unit (Coupler)

|

Material |

Maximum Working Pressure |

Test Pressure |

Minimum Burst Pressure |

|

Aluminium |

10 bar / 145 psi |

15 bar / 218 psi |

50 bar / 726 psi |

|

Brass / Gunmetal |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Stainless Steel |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Titan |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

Hastelloy |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

|

PEEK |

6 bar / 87 psi |

9 bar / 131 psi |

30 bar / 435 psi |

2½" and 3" in BSP, NPT and flanged inlet.

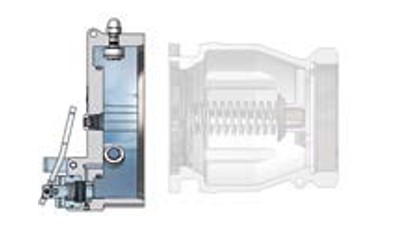

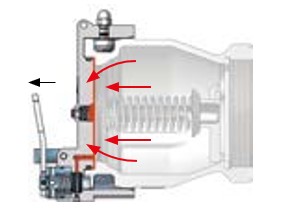

For road and rail tanker bottom loading/unloading, tanks and containers, or on any application where product contamination and spillage needs to be minimized.

Petroleum products: gasoline, diesel, oil etc. Chemical products: ethylene oxide, propylene oxide, acrylonitrile, butadiene, ammonia, vinyl chloride, toluene, xylene, sulphuric acid, phenol etc.

Gas: vapor recovery/balance systems forfor various media.

Dry powder

Aluminium, brass/gunmetal, stainless steel, Hastelloy and PEEK. Other materials on request.

Standard seals in FPM (Viton®), EPDM, Chemraz®, Kalrez®, NBR. Other materials on request.

Allows maximum product transfer with minimal losses.

1500 litres/minute (fuel)

To avoid product contamination caused by connecting a hose unit to the wrong tank unit, selective versions of the hose and tank units are available. Each unit has a number of selective positions, desig- nated by a coded part number according to the coup- ling size – specify when placing order. See page 32 ff.

Compatible with couplings of other manufacturers.

All hose units are supplied with an integrated swivel.

According to NATO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F 2½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

1,0 |

2.2 |

T312D1101B |

|

F 3" BSP |

1,0 |

2.2 |

T314D1101B |

|||

|

F 2½" NPT |

— |

1,0 |

2.2 |

T313D1101 |

||

|

F 3" NPT |

1,1 |

2.4 |

T315D1101 |

|||

|

F 2½" BSP |

GM |

PUR (Polyurethane) |

2,7 |

6.0 |

T312D2201B |

|

|

F 3" BSP |

2,9 |

6.4 |

T314D2201B |

|||

|

F 2½" NPT |

— |

2,9 |

6.4 |

T313D2201 |

||

|

F 3" NPT |

3,2 |

7.1 |

T315D2201 |

|||

|

F 2½" BSP |

SS |

PTFE (Teflon®) |

2,5 |

5.5 |

T312B4401A |

|

|

F 3" BSP |

3,1 |

6.8 |

T314B4401A |

|||

|

F 2½" NPT |

— |

2,7 |

6.0 |

T313B4401 |

||

|

F 3" NPT |

3,7 |

8.2 |

T315B4401 |

|||

|

F 2½" BSP |

Hastelloy |

PTFE (Teflon®) |

2,6 |

5.7 |

T312A7701A |

|

|

F 3" BSP |

|

|

T314A7701A |

|||

|

F 2½" NPT |

— |

|

|

T313A7701 |

||

|

F 3" NPT |

|

|

T315A7701 |

|||

|

F 2½" BSP |

PEEK |

PTFE (Teflon®) |

|

|

T312A9901A |

|

|

F 3" BSP |

|

|

T314A9901A |

|||

|

F 2½" NPT |

— |

|

|

T313A9901 |

||

|

F 3" NPT |

|

|

T315A9901 |

|||

1) F = Female thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® and Teflon® are registred trademarks of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

2½" BSP |

|

|

1,0 |

2.2 |

T380A1101 |

|

|

3" BSP |

Al |

|

|

|

T382A1101 |

|

|

2½" NPT |

|

|

T381A1101 |

|||

|

3" NPT |

|

Standard: |

|

|

T383A1101 |

|

|

2½" BSP |

|

|

|

T380A2201 |

||

|

|

FPM/FKM |

|||||

|

3" BSP |

|

|

T382A2201 |

|||

|

GM |

(Viton®)

Other on |

|||||

|

2½" NPT |

|

|

T381A2201 |

|||

|

3" NPT |

|

|

T383A2201 |

|||

|

|

request. |

|||||

|

2½" BSP |

|

|

|

T380A4401 |

||

|

3" BSP |

SS |

|

|

|

T382A4401 |

|

|

2½" NPT |

|

|

T381A4401 |

|||

|

3" NPT |

|

|

|

|

T383A4401 |

|

1) M = Male thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® and Teflon® are registred trademarks of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 210 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

2,1 |

4.6 |

T320D1101 |

|

DN 65 PN 10 / 16 Type A |

1,6 |

3.5 |

T333D1101 |

||

|

DN 80 PN 10 / 16 Type A |

1,8 |

4.0 |

T336D1101 |

||

|

2½" ASA 150 |

1,7 |

3.8 |

T359D1101 |

||

|

3" ASA 150 |

1,8 |

4.0 |

T361D1101 |

||

|

DIN 28459 'TW 1' / DN 80 |

1,3 |

2.9 |

T365D1101 |

||

|

DIN 28459 'TW 3' / DN 100 |

1,7 |

3.8 |

T366D1101 |

||

|

3" TTMA |

1,4 |

3.1 |

T367D1101 |

||

|

4" TTMA |

1,5 |

3.3 |

T368D1101 |

||

|

undrilled Ø 210 mm |

GM |

6,2 |

13.7 |

T320D2201 |

|

|

DN 65 PN 10 / 16 Type B |

4,9 |

10.8 |

T333D2201 |

||

|

DN 65 PN 25 / 40 Type B |

|

|

T334D2201 |

||

|

DN 80 PN 10 / 16 Type B |

|

|

T336D2201 |

||

|

DN 80 PN 25 / 40 Type B |

|

|

T337D2201 |

||

|

2½" ASA 150 |

4,4 |

9.7 |

T359D2201 |

||

|

2½" ASA 300 |

|

|

T360D2201 |

||

|

3" ASA 150 |

4,4 |

9.7 |

T361D2201 |

||

|

3" ASA 300 |

|

|

T362D2201 |

||

|

DIN 28459 'TW 1' / DN 80 |

4,4 |

9.7 |

T365D2201 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

T366D2201 |

||

|

3" TTMA |

|

|

T367D2201 |

||

|

4" TTMA |

4,2 |

9.3 |

T368D2201 |

||

|

undrilled Ø 210 mm |

SS |

|

|

T320B4401 |

|

|

o. Bohrungen Ø 210 mm **) |

|

|

T320B4401F |

||

|

DN 65 PN 25 / 40 Type E *) |

|

|

T332B4401 |

||

|

DN 65 PN 10 / 16 Type B ) |

4,2 |

9.3 |

T333B4401 |

||

|

DN 65 PN 10 / 16 Type B ** |

|

|

T333B4401F |

||

|

DN 65 PN 25 / 40 Type B ) |

4,3 |

9.5 |

T334B4401 |

||

|

DN 65 PN 25 / 40 Type B ** |

4,3 |

9.5 |

T334B4401F |

||

|

DN 80 PN 10 / 16 Type E *) |

|

|

T335B4401 |

||

|

DN 80 PN 10 / 16 Type B ) |

4,7 |

10.4 |

T336B4401 |

||

|

DN 80 PN 10 / 16 Type B ** |

|

|

T336B4401F |

||

|

DN 80 PN 25 / 40 Type B ) |

|

|

T337B4401 |

||

|

DN 80 PN 25 / 40 Type B ** |

|

|

T337B4401F |

||

|

2½" ASA 150 ) |

4,0 |

8.8 |

T359B4401 |

||

|

2½" ASA 150 ** |

|

|

T359B4401F |

||

|

2½" ASA 300 ) |

4,5 |

9.9 |

T360B4401 |

||

|

2½" ASA 300 ** |

4,5 |

9.9 |

T360B4401F |

||

|

3" ASA 150 ) |

4,5 |

9.9 |

T361B4401 |

||

|

3" ASA 150 ** |

|

|

T361B4401F |

||

|

3" ASA 300 ) |

|

|

T362B4401 |

||

|

3" ASA 300 ** |

|

|

T362B4401F |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

T365B4401 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

T366B4401 |

||

|

3" TTMA |

|

|

T367B4401 |

||

|

4" TTMA |

|

|

T368B4401 |

||

*) Type E (with spigot),

EN 1092-1, see page 44

**) Flange with standard thickness

1) PN 10 / 16 / 25 / 40 = EN 1092

(types see page 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = old standard TW, 10 bar. TTMA = Standard of the Truck Trailer Manufacturers Association

2) Material: Al = Aluminium,

GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request.

Viton® is a registred trademark of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

Normec (120 x 120 mm) |

Al |

Standard: FPM/FKM (Viton®) |

|

|

T3107D1101 |

|

Normec (120 x 120 mm) |

GM |

|

|

T3107D2201 |

|

1) Normec = with drilling for Italian road tanker connection

2) Material: Al = Aluminium, GM = Gunmetal

3) Standarddichtung FPM/FKM. Alternative Materialien,

According to NATO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring 3) |

Thread Seal |

kg |

lbs |

|||

|

F 2½" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethan) |

3,3 |

7.3 |

S312B1101B |

|

F 3" BSP |

3,6 |

7.9 |

S314B1101B |

|||

|

F 2½" NPT |

— |

3,4 |

7.5 |

S313B1101 |

||

|

F 3" NPT |

3,5 |

7.7 |

S315B1101 |

|||

|

F 2½" BSP |

GM |

PUR (Polyurethan) |

7,3 |

16.1 |

S312B2201B |

|

|

F 3" BSP |

7,4 |

16.3 |

S314B2201B |

|||

|

F 2½" NPT |

— |

|

|

S313B2201 |

||

|

F 3" NPT |

7,6 |

16.8 |

S315B2201 |

|||

|

F 2½" BSP |

SS |

PTFE |

6,7 |

14.8 |

S312B4401A |

|

|

F 3" BSP |

6,6 |

14.6 |

S314B4401A |

|||

|

F 2½" NPT |

— |

6,6 |

14.6 |

S313B4401 |

||

|

F 3" NPT |

6,6 |

14.6 |

S315B4401 |

|||

|

F 2½" BSP |

Hastelloy |

PTFE |

6,8 |

15.0 |

S312A7701A |

|

|

F 3" BSP |

|

|

S314A7701A |

|||

|

F 2½" NPT |

— |

|

|

S313A7701 |

||

|

F 3" NPT |

|

|

S315A7701 |

|||

|

F 2½" BSP |

PEEK |

PTFE |

|

|

S312A9901A |

|

|

F 3" BSP |

|

|

S314A9901A |

|||

|

F 2½" NPT |

— |

|

|

S313A9901 |

||

|

F 3" NPT |

|

|

S315A9901 |

|||

According to NATO STANAG 3756

|

Flange 1B) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 210 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

|

|

S320B1101 |

|

DN 65 PN 10 / 16 Type A |

10,0 |

22.1 |

S333B1101 |

||

|

DN 80 PN 10 / 16 Type A |

|

|

S336B1101 |

||

|

2" ASA 150 |

|

|

S357B1101 |

||

|

2½" ASA 150 |

|

|

S359B1101 |

||

|

3" ASA 150 |

|

|

S361B1101 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S365B1101 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S366B1101 |

||

|

3" TTMA |

|

|

S367B1101 |

||

|

4" TTMA |

|

|

S368B1101 |

||

|

undrilled Ø 210 mm |

GM |

|

|

S320B2201 |

|

|

DN 65 PN 10 / 16 Type B |

|

|

S333B2201 |

||

|

DN 65 PN 25 / 40 Type B |

|

|

S334B2201 |

||

|

DN 80 PN 10 / 16 Type B |

|

|

S336B2201 |

||

|

DN 80 PN 25 / 40 Type B |

|

|

S337B2201 |

||

|

2" ASA 150 |

|

|

S357B2201 |

||

|

2½" ASA 150 |

|

|

S359B2201 |

||

|

2½" ASA 300 |

|

|

S360B2201 |

||

|

3" ASA 150 |

|

|

S361B2201 |

||

|

3" ASA 300 |

|

|

S362B2201 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S365B2201 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S366B2201 |

||

|

3" TTMA |

|

|

S367B2201 |

||

|

4" TTMA |

|

|

S368B2201 |

||

|

undrilled Ø 210 mm |

SS |

|

|

S320B4401 |

|

|

undrilled Ø 210 mm**) |

|

|

S320B4401F |

||

|

DN 65 PN 25 / 40 Type E*) |

|

|

S332B4401 |

||

|

DN 65 PN 10 / 16 Type B |

10,0 |

22.1 |

S333B4401 |

||

|

DN 65 PN 10 / 16 Type B**) |

|

|

S333B4401F |

||

|

DN 65 PN 25 / 40 Type B |

|

|

S334B4401 |

||

|

DN 65 PN 25 / 40 Type B**) |

|

|

S334B4401F |

||

|

DN 80 PN 10 / 16 Type E*) |

|

|

S335B4401 |

||

|

DN 80 PN 10 / 16 Type B ) |

|

|

S336B4401 |

||

|

DN 80 PN 10 / 16 Type B** |

|

|

S336B4401F |

||

|

DN 80 PN 25 / 40 Type B |

|

|

S337B4401 |

||

|

DN 80 PN 25 / 40 Type B**) |

|

|

S337B4401F |

||

|

2" ASA 150 ) |

|

|

S357B4401 |

||

|

2" ASA 150** |

|

|

S357B4401F |

||

|

2½" ASA 150 ) |

6,6 |

14.6 |

S359B4401 |

||

|

2½" ASA 150** |

6,6 |

14.6 |

S359B4401F |

||

|

2½" ASA 300 |

|

|

S360B4401 |

||

|

2½" ASA 300**) |

|

|

S360B4401F |

||

|

3" ASA 150 |

|

|

S361B4401 |

||

|

3" ASA 150**) |

|

|

S361B4401F |

||

|

3" ASA 300 |

|

|

S362B4401 |

||

|

3" ASA 300**) |

|

|

S362B4401F |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S365B4401 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S366B4401 |

||

|

3" TTMA |

|

|

S367B4401 |

||

|

4" TTMA |

|

|

S368B4401 |

||

*) Type E (with spigot),

EN 1092-1, see page 44

**) Flange with standard thickness

1A) F = Female thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

1B) PN 10 / 16 / 25 / 40 = EN 1092

(types see page 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = old standard TW, 10 bar. TTMA = Truck Trailer Manufacturers Association

2) Material: Al = Aluminium, GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

Viton® and Teflon® are registred trademarks of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

kg |

lbs |

||||

|

DIN 28459 'TW 1' / DN 80 |

|

Standard: |

1,6 |

3.5 |

T465I1101 |

|

|

DIN 28459 'TW 3' / DN 100 |

|

1,6 |

3.5 |

T466I1101 |

||

|

FPM/FKM |

||||||

|

Al |

(Viton®) |

|||||

|

3" TTMA |

|

|

T467I1101 |

|||

|

|

Other on |

|||||

|

|

request. |

|||||

|

4" TTMA |

|

|

T468I1101 |

|||

15° dropped Tank unit with flange connection makes it easier to connect when installed in high position and reduces hose wear.

1) DIN 28459 = old standard TW, 10 bar. TTMA = Truck Trailer Manufacturers Association

2) Material: Al = Aluminium

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

Viton® is a registred trademark of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

Normec (120x120 mm) |

Al |

Standard: FPM/FKM (Viton®) |

|

|

T4107D1101 |

|

Normec (120x120 mm) |

GM |

|

|

T4107D2201 |

|

1) Normec = with drilling for Italian road tanker connection

2) Material: Al = Aluminium, GM = Gunmetal

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

Viton® is a registred trademark of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

Thread Seal |

kg |

lbs |

|||

|

F 3" BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR |

3,8 |

8.4 |

S414B1101B |

|

F 3" NPT |

— |

3,9 |

8.6 |

S415B1101 |

||

|

F 3" BSP |

GM |

PUR |

8,4 |

18.5 |

S414B2201B |

|

|

F 3" NPT |

— |

9,0 |

19.8 |

S415B2201 |

||

|

F 3" BSP |

SS |

PTFE |

8,4 |

18.5 |

S414B4401A |

|

|

F 3" NPT |

— |

8,7 |

19.2 |

S415B4401 |

||

|

F 3" BSP |

Hastelloy |

PTFE |

|

|

S414A7701B |

|

|

F 3" NPT |

— |

8,1 |

17.7 |

S415A7701 |

||

|

F 3" BSP |

PVDF/Hastelloy |

PTFE |

|

|

S414A8701B |

|

|

F 3" BSP |

PEEK |

PTFE |

|

|

S414A9901B |

|

|

F 3" NPT |

— |

|

|

S415A9901 |

||

1) F = Female thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 210 mm |

Al |

Standard: FPM/FKM (Viton®) Other on request. |

|

|

S420B1101 |

|

DN 80 PN 10 / 16 Type A |

|

|

S436B1101 |

||

|

3" ASA 150 |

5,5 |

12.1 |

S461B1101 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S465B1101 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S466B1101 |

||

|

3" TTMA |

|

|

S467B1101 |

||

|

4" TTMA |

5,5 |

12.1 |

S468B1101 |

||

|

undrilled Ø 210 mm |

GM |

|

|

S320B2201 |

|

|

DN 80 PN 10 / 16 Type B |

|

|

S436B2201 |

||

|

DN 80 PN 25 / 40 Type B |

|

|

S437B2201 |

||

|

3" ASA 150 |

|

|

S461B2201 |

||

|

3" ASA 300 |

|

|

S462B2201 |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S465B2201 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S466B2201 |

||

|

3" TTMA |

|

|

S467B2201 |

||

|

4" TTMA |

|

|

S468B2201 |

||

|

undrilled Ø 210 mm |

SS |

|

|

S420B4401 |

|

|

o. Bohrungen Ø 210 mm**) |

|

|

S420B4401F |

||

|

DN 80 PN 10/ 6 Type B |

12,7 |

28.0 |

S436B4401 |

||

|

DN 80 PN 10 / 16 Type B**) |

|

|

S436B4401F |

||

|

DN 80 PN 25 / 40 Type B |

|

|

S437B4401 |

||

|

DN 80 PN 25 / 40 Type B**) |

|

|

S437B4401F |

||

|

DN 80 PN 25 / 40 Type E |

|

|

S435B4401F |

||

|

3" ASA 150 |

13,2 |

29.1 |

S461B4401 |

||

|

3" ASA 150 **) |

13,2 |

29.1 |

S461B4401F |

||

|

3" ASA 300 |

|

|

S462B4401 |

||

|

3" ASA 300 **) |

14,6 |

32.2 |

S462B4401F |

||

|

DIN 28459 'TW 1' / DN 80 |

|

|

S465B4401 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S466B4401 |

||

|

3" TTMA |

|

|

S467B4401 |

||

|

4" TTMA |

|

|

S468B4401 |

||

|

undrilled Ø 210 mm |

PEEK |

|

|

S420B9901 |

|

|

DN 80 PN 10 / 16 Type B |

|

|

S436B9901 |

||

|

3" ASA 150 |

|

|

S461B9901 |

||

*) Type E (with spigot),

EN 1092-1, see page 44

**) Flange with standard thickness

1) PN 10 / 16 / 25 / 40 = EN 1092

(types see page 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = old standard TW, 10 bar. TTMA = Truck Trailer Manufacturers Association

2) Material: Al = Aluminium, GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

Viton® and Teflon® are registred trademarks of DuPont, DuPont Elastomers.

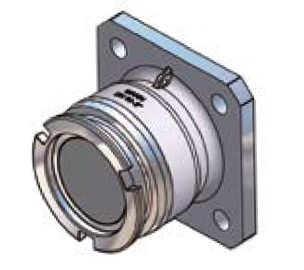

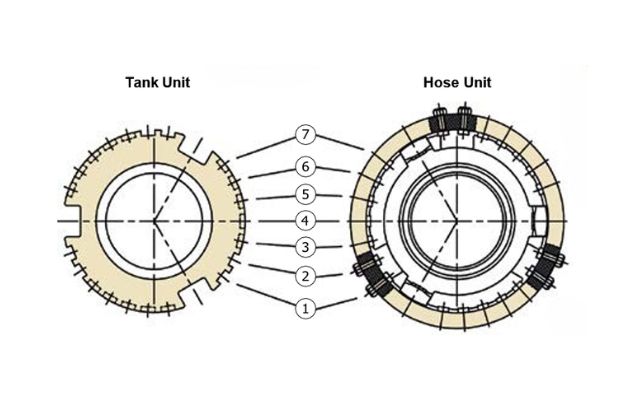

Tank Unit (Adapter) and Hose Unit (Coupler)

|

Material |

Maximum Working Pressure |

Test Pressure |

Minimum Burst Pressure |

|

Aluminium |

10 bar / 145 psi |

15 bar / 218 psi |

50 bar / 726 psi |

|

Brass / Gunmetal |

16 bar / 232 psi |

24 bar / 348 psi |

80 bar / 1160 psi |

|

Stainless Steel |

25 bar / 363 psi |

37,5 bar / 544 psi |

125 bar / 1813 psi |

4" in BSP, NPT and flanged inlet.

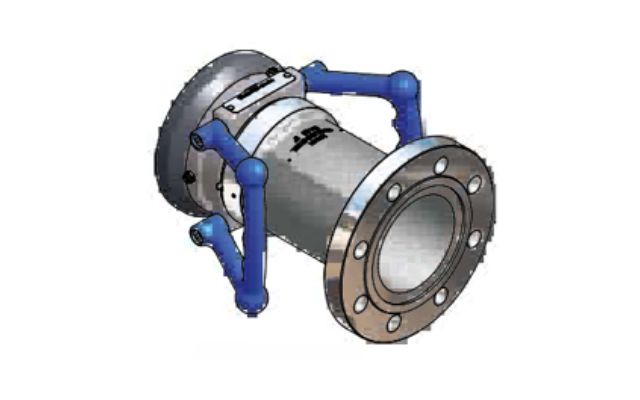

Recommended for HiFlo-loading / unloading of rail tankers, aviation refuellers and road tankers. Also suitable for ship to shore transfer, ship to ship transfer and ship to rig transfer or on any application where spillage needs to be minimized.

Petroleum products: gasoline, diesel, oil etc. Chemical products: ethylene oxide, propylene oxide, acrylonitrile, butadiene, ammonia, vinyl chloride, toluene, xylene, sulphuric acid, phenol etc.

Gas: vapor recovery/balance systems forfor various media.

Dry powder

Aluminium, brass/gunmetal, stainless steel, Hastelloy and PEEK. Other materials on request.

StandardSeals FPM (Viton®), EPDM, FFKM (Chemraz®, Kalrez®), NBR. Other on request.

Allows maximum product transfer with minimal losses

3500 litres/minute (fuel)

To avoid product contamination caused by connecting a hose unit to the wrong tank unit, selective versions of the hose and tank units are available. Each unit has a number of selective positions, desig- nated by a coded part number according to the coup- ling size – specify when placing order. See page 32 ff.

Compatible with couplings of other manufacturers.

All hose units are supplied with an integrated swivel.

|

Connection 1) Inch/DN |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|||

|

O-Ring |

Thread Seal |

kg |

lbs |

||||

|

F 4" BSP |

Al |

Standard: |

PUR |

2,5 |

5.5 |

T516A1101B |

|

|

F 4" NPT |

— |

2,8 |

6.2 |

T517A1101 |

|||

|

|

FPM/FKM |

||||||

|

F 4" BSP |

|

PUR |

7,0 |

15.4 |

T516D2201B |

||

|

GM |

(Viton®) Other on |

||||||

|

F 4" NPT |

— |

7,7 |

17.0 |

T517D2201 |

|||

|

F 4" BSP |

|

PTFE |

6,0 |

13.2 |

T516B4401A |

||

|

SS |

request. |

||||||

|

F 4" NPT |

— |

6,4 |

14.1 |

T517B4401 |

|||

1) F = Female thread, BSP = EN ISO 228, NPT = ANSI B1.20.1

2) Material: Al = Aluminium, GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

Viton® is a registred trademark of DuPont, DuPont Elastomers.

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 230 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

3,2 |

7.1 |

T521D1101 |

|

DN 100 PN 10 / 16 Type B |

3,1 |

6.8 |

T539D1101 |

||

|

4" ASA 150 |

3,2 |

7.1 |

T563D1101 |

||

|

DIN 28459 'TW 3' / DN 100 |

2,6 |

5.7 |

T566D1101 |

||

|

4" TTMA |

2,6 |

5.7 |

T568D1101 |

||

|

undrilled Ø 230 mm |

GM |

|

|

T521D2201 |

|

|

DN 100 PN 10 / 16 Type B |

|

|

T539D2201 |

||

|

DN 100 PN 25 / 40 Type B |

|

|

T540D2201 |

||

|

4" ASA 150 |

|

|

T563D2201 |

||

|

4" ASA 300 psi |

|

|

T564D2201 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

T566D2201 |

||

|

4" TTMA |

|

|

T568D2201 |

||

|

undrilled Ø 230 mm |

SS |

|

|

T521B4401 |

|

|

o. Bohrungen Ø 230 mm**) |

|

|

T521B4401F |

||

|

DN 100 PN 10 / 16 Type B |

8,7 |

19.2 |

T539B4401 |

||

|

DN 100 PN 10 / 16 Type B**) |

8,6 |

19.0 |

T539B4401F |

||

|

DN 100 PN 25 / 40 Type B |

|

|

T540B4401 |

||

|

DN 100 PN 25 / 40 Type B**) |

|

|

T540B4401F |

||

|

DN 100 PN 25 / 40 Type E |

|

|

T538B4401F |

||

|

4" ASA 150 |

8,9 |

19.6 |

T563B4401 |

||

|

4" ASA 150 **) |

8,9 |

19.6 |

T563B4401F |

||

|

4" ASA 300 psi |

12 |

26.5 |

T564B4401 |

||

|

4" ASA 300 psi**) |

12 |

26.5 |

T564B4401F |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

T566B4401 |

||

|

4" TTMA |

2,5 |

5.5 |

T568B4401 |

||

*) Type E (with spigot),

EN 1092-1, see page 44

**) Flange with standard thickness

1) PN 10 / 16 / 25 / 40 = EN 1092

(types see page 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = old standard TW, 10 bar. TTMA = Truck Trailer Manufacturers Association

2) Material: Al = Aluminium, GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

Viton® is a registred trademark of DuPont, DuPont Elastomers.

According to NATO STANAG 3756

|

Connection 1) Inch/DN |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

||

|

O-Ring |

Thread Seal |

kg |

lbs |

|||

|

F 4 BSP |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

PUR (Polyurethane) |

7,6 |

16.8 |

S516B1101B |

|

F 4" ASSPT |

|

|

S5136B1101B |

|||

|

F 4" NPT |

— |

7,9 |

14.2 |

S517B1101 |

||

|

F 4" BSP |

GM |

PUR (Polyurethane) |

17,5 |

38.6 |

S516B2201B |

|

|

F 4" ASSPT |

|

|

S5136B2201B |

|||

|

F 4" NPT |

— |

17,7 |

39.0 |

S517B2201 |

||

|

F 4" BSP |

SS |

PTFE |

15,6 |

34.4 |

S516B4401A |

|

|

F 4" ASSPT |

|

|

S5136B4401A |

|||

|

F 4" NPT |

— |

15,9 |

35.0 |

S517B4401 |

||

1) F = Female thread, BSP = EN ISO 228, NPT = ANSI B1.20.3,

ASSPT = American Straight Pipe Thread, identical to NPS. NPT male threads can be connected with ASSPT female treads.

2) Material: Al = Aluminium, GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

According to NATO STANAG 3756

|

Flange 1) |

Body Material 2) |

Seal 3) |

Weight ≈ |

Mann Tek Code No. |

|

|

O-Ring |

kg |

lbs |

|||

|

undrilled Ø 230 mm |

Al |

Standard: FPM/FKM (Viton®)

Other on request. |

|

|

S521B1101 |

|

DN 100 PN 10 / 16 Type B |

9,3 |

20.0 |

S539B1101 |

||

|

4" ASA 150 |

9,4 |

20.7 |

S563B1101 |

||

|

4" TTMA |

8,7 |

19.2 |

S568B1101 |

||

|

DIN 28459 'TW 3' / DN 100 |

8,7 |

19.2 |

S566B1101 |

||

|

undrilled Ø 230 mm |

Br |

|

|

S521B2201 |

|

|

DN 100 PN 10 / 16 Type B |

|

|

S539B2201 |

||

|

DN 100 PN 25 / 40 Type B |

23,9 |

52.7 |

S540B2201 |

||

|

4" ASA 150 |

23,9 |

52.7 |

S563B2201 |

||

|

4" ASA 300 psi |

|

|

S564B2201 |

||

|

4" TTMA |

|

|

S568B2201 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S566B2201 |

||

|

undrilled Ø 230 mm |

SS |

16,1 |

35.5 |

S521B4401 |

|

|

o. Bohrungen Ø 230 mm **) |

|

|

S521B4401F |

||

|

DN 100 PN 10 / 16 Type B |

16,1 |

35.5 |

S539B4401 |

||

|

DN 100 PN 10 / 16 Type B **) |

16,1 |

35.5 |

S539B4401F |

||

|

DN 100 PN 25 / 40 Type B |

16,1 |

35.5 |

S540B4401 |

||

|

DN 100 PN 25 / 40 Type B **) |

|

|

S540B4401F |

||

|

DN 100 PN 25 / 40 Type E |

|

|

S538B4401F |

||

|

4" ASA 150 |

21,0 |

46.3 |

S563B4401 |

||

|

4" ASA 150 **) |

21,0 |

46.3 |

S563B4401 |

||

|

4" ASA 300 psi |

16,1 |

35.5 |

S564B4401 |

||

|

4" ASA 300 psi **) |

|

|

S564B4401F |

||

|

4" TTMA |

8,7 |

19.2 |

S568B4401 |

||

|

DIN 28459 'TW 3' / DN 100 |

|

|

S566B4401 |

||

*) Type E (with spigot),

EN 1092-1, see page 44

**) Flange with standard thickness

1) PN 10 / 16 / 25 / 40 = EN 1092

(types see page 44),

ASA = ANSI B16.5 (150 o. 300 psi),

DIN 28459 = old standard TW, 10 bar. TTMA = Truck Trailer Manufacturers Association

2) Material: Al = Aluminium,

GM = Gunmetal, SS = Stainless Steel

3) Standard seal FPM/FKM. Alternative materials, e. g. EPDM, Chemraz®, Kalrez®, NBR or HNBR on request

Viton® is a registred trademark of DuPont, DuPont Elastomers.

Tank Unit (Adapter) and Hose Unit (Coupler)

|

Material |

Maximum Working Pressure |

Test Pressure |

Minimum Burst Pressure |

|

Aluminium |

10 bar / 145 psi |

15 bar / 218 psi |

50 bar / 726 psi |

|

Stainless Steel |