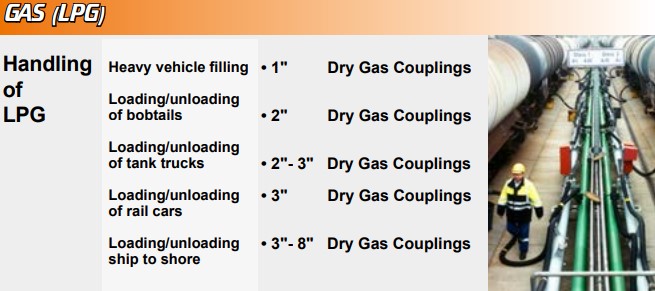

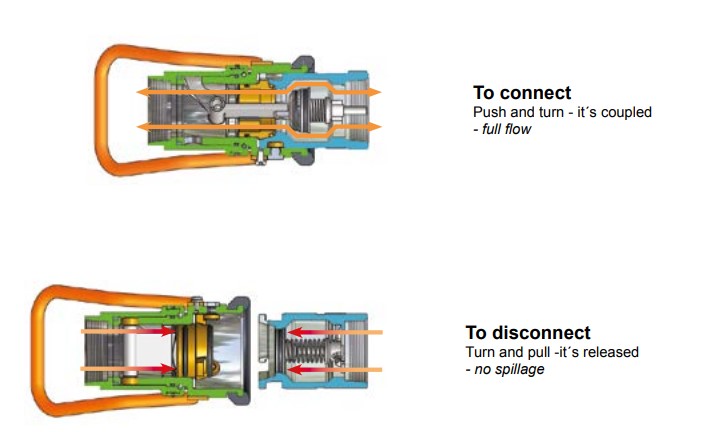

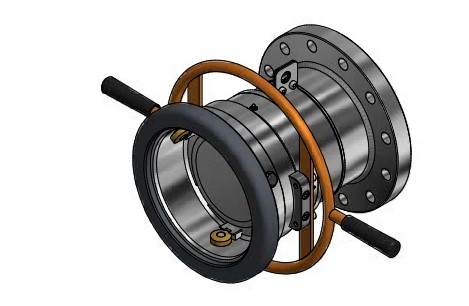

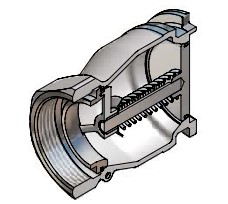

The Dry Gas Coupling has been developed for a safe and quick connection and disconnection of hoses and loading arms to tank trucks, rail tankers and tank containers. During connection and after disconnection there is no spillage.

Suitable for handling a range of LPG applications - Propane and Butane but alsofor other applications with similar requirements the Dry Gas Coupling is useful. The robust design, easy servicing and high level of security assures safe and frequent use on a long term basis. This protects the environment and the media handled, reduces the risk of accidents and saves money.

A modular design with several optional features makes it possible to find individual solutions for your special application.

.jpg)

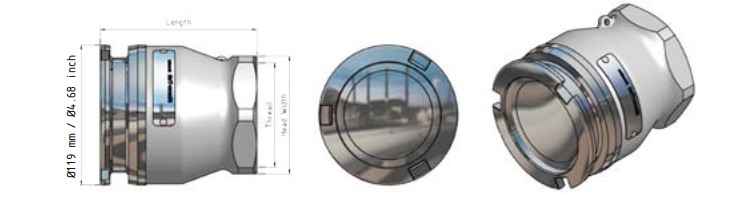

Available with ACME threads for assembling direct on existing connections.

Other handle and material on request.

| Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| ¾” BSP | 131 / 5.16 | 50 / 1.97 | 1,9 / 4.2 | M101A4401A |

| ¾” NPT | 135 / 5.31 | 50 / 1.97 | 2,0 / 4.4 | M102A4401 |

| 1” BSP | 133 / 5.24 | 50 / 1.97 | 1,9 / 4.2 | M103A4401A |

| 1” NPT | 137 / 5.39 | 50 / 1.97 | 2,0 / 4.4 | M104A4401 |

| 1 ¼” BSP | 140 / 5.51 | 50 / 1.97 | 1,9 / 4.2 | M105A4401A |

| 1 ¼” NPT | 144 / 5.67 | 50 / 1.97 | 2,0 / 4.4 | M106A4401 |

Other handle and material on request.

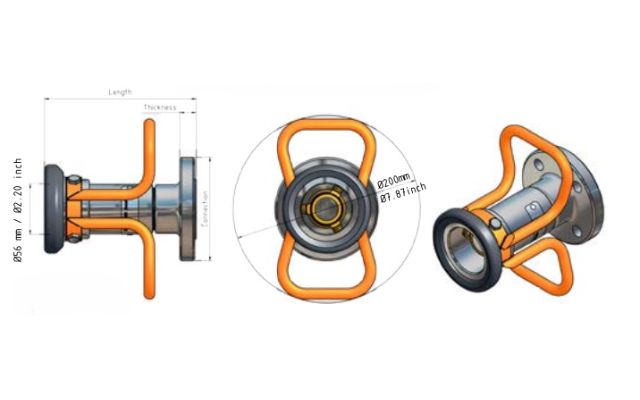

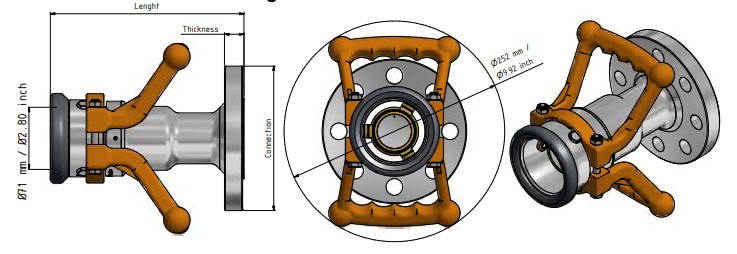

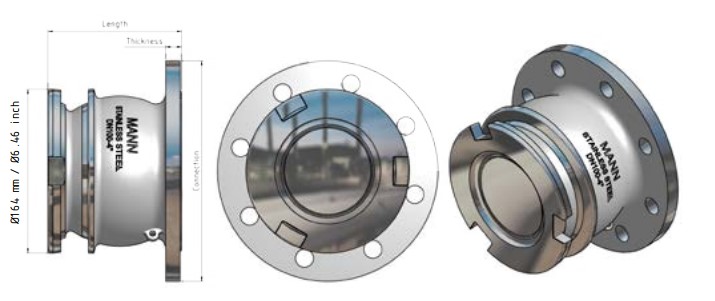

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| ¾” ANSI Cl. 300 | 167 / 6.57 | 15,9 / 0.63 | 3,2 / 7.1 | M150A4401 |

| DN25 PN25/40 | 169 / 6.65 | 18,0 / 0.71 | 3,4 / 7.5 | M124A4401 |

| 1” ANSI Cl. 300 | 168 / 6.61 | 17,5 / 0.69 | 3,4 / 7.5 | M152A4401 |

| DN32 PN25/40 | 169 / 6.65 | 18,0 / 0.71 | 3,6 / 7.9 | M126A4401 |

| 1 ¼” ANSI Cl. 300 | 170 / 6.69 | 19,0 / 0.75 | 3,6 / 7.9 | M154A4401 |

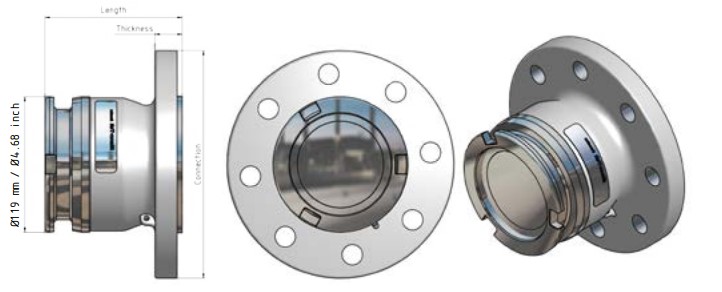

Available with ACME threads for assembling direct on existing connections.

Other handle and material on request.

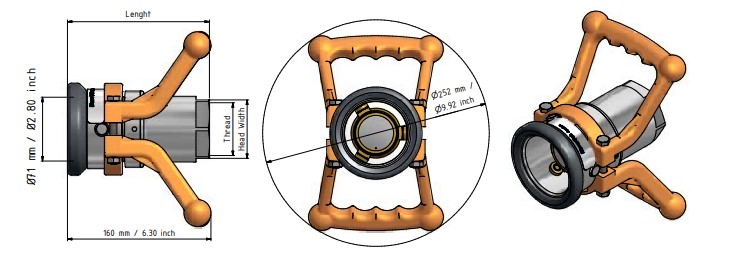

|

Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| 1 ½” BSP | 152 / 5.98 | 65 / 2.56 | 3,1 / 6.8 | M207A4401A |

|

1 ½” NPT |

155 / 6.10 |

65 / 2.56 |

3,2 / 7.0 |

M208A4401 |

| 2” BSP | 155 / 6.10 | 65 / 2.56 | 2,9 / 6.4 |

M210A4401A |

|

2” NPT |

156 / 6.10 |

65 / 2.56 |

3,0 / 6.6 |

M211A4401 |

Other handle, flange and material on request.

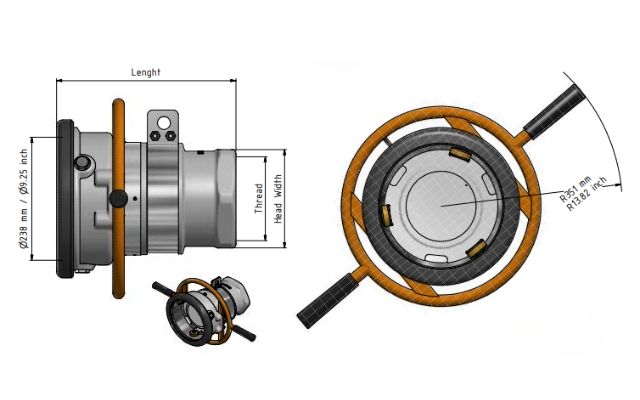

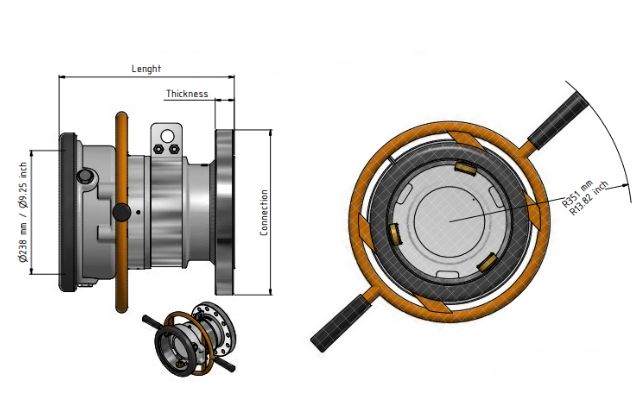

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN40 PN25/40 | 216 / 8.50 | 18 / 0.71 | 5,3 / 11.7 | M228A4401 |

| 1 ½” ANSI Cl. 300 | 218 / 8.58 | 21 / 0.83 | 5,7 / 12.6 | M256A4401 |

| DN50 PN25/40 | 218 / 8.58 | 20 / 0.79 | 6,0 / 13.2 | M231A4401 |

| 2” ANSI Cl. 300 | 220 / 8.66 | 22 / 0.87 | 6,1 / 13.4 | M258A4401 |

Other handle and material on request.

Available with ACME and Witworth threads (ie. W90) for assembling direct on existing connections.

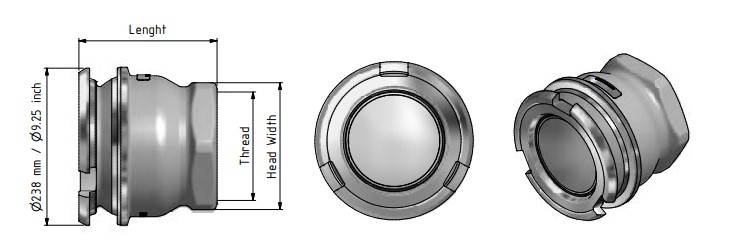

|

Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| 2 ½” BSP | 192 / 7.56 | 100 / 3.94 | 8,8 / 19.4 |

M412B4401A |

|

2 ½” NPT |

200 / 7.87 |

100 / 3.94 |

9,1 / 20.1 |

M413B4401 |

| 3” BSP | 194 / 7.64 | 100 / 3.94 | 8,1 / 17.9 | M414B4401A |

|

3” NPT |

202 / 7.95 |

100 / 3.94 |

8,4 / 18.5 |

M415B4401 |

Other handle, flange and material on request.

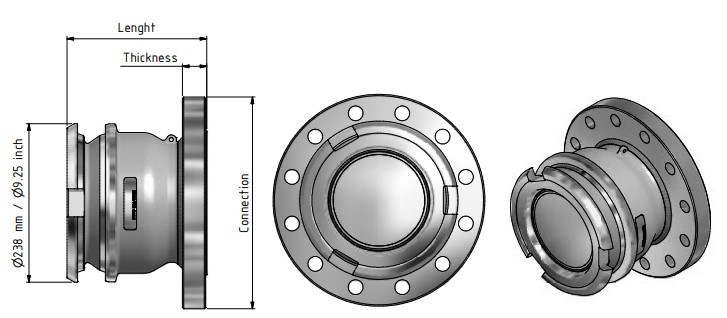

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN65 PN25/40 | 260 / 10.24 | 22,0 / 0.87 | 12,6 / 27.8 | M434B4401 |

| 2 ½” ANSI Cl. 300 | 264 / 10.39 | 25,4 / 1.0 | 13,3 / 29.3 | M460B4401 |

| DN80 PN25/40 | 267 / 10.51 | 24,0 / 0.94 | 13,2 / 29.1 | M437B4401 |

| 3” ANSI Cl. 300 | 263 / 10.35 | 28,6 / 1.13 | 15,1 / 33.3 | M462B4401 |

Other handle and material on request.

|

Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| 4” BSP | 223 / 8.78 | 130 / 5.12 | 15,7 / 34.6 |

M516B4401A |

|

4” NPT |

232 / 9.13 |

130 / 5.12 |

16,0 / 35.3 |

M517B4401 |

Other handle and material on request.

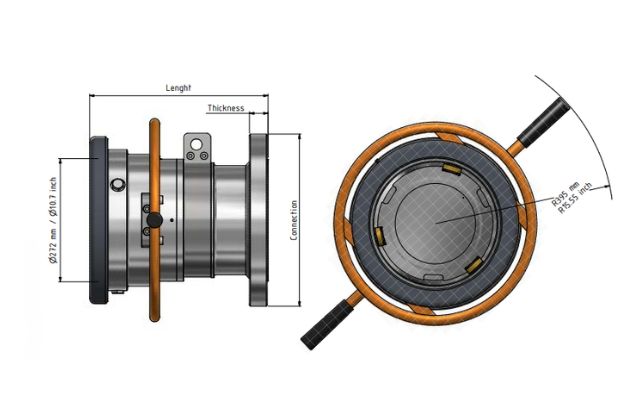

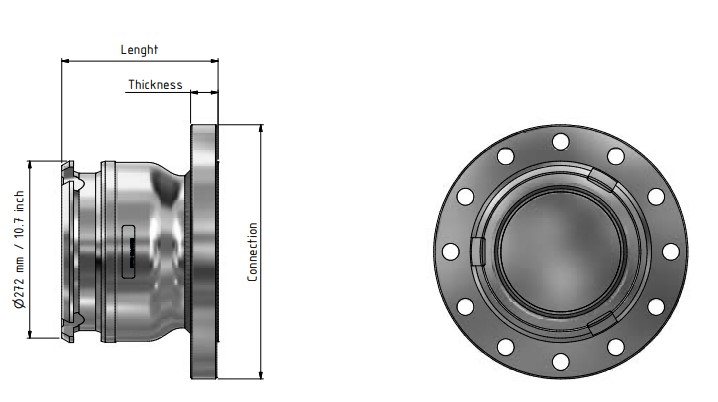

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN100 PN25/40 | 233 / 9.17 | 24,0 / 0.94 | 20,8 / 45.9 | M540B4401 |

| 4” ANSI Cl. 300 | 241 / 9.49 | 31,7 / 1.25 | 24,3 / 53.6 | M564B4401 |

Other handle and material on request.

|

Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| 6” BSP | 343 / 13.5 | 190 / 7.48 | 49 / 108 | M6110B4401A |

|

6” NPT |

349 / 13.74 |

190 / 7.48 |

49,5 / 109.1 |

M6111B4401 |

Other handle and material on request.

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN150 PN25/40 | 327,5 / 12.89 | 28,0 / 1.1 | 56,5 / 124.6 | M646B4401 |

| 6" ANSI Cl.300 | 336 / 13.23 | 36,5 / 1.44 | 63 / 138.9 | M6101B4401 |

Other handle and material on request.

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN200 PN25 | 384 / 15.12 | 30,0 / 1.18 | 101,5 / 223.8 | M8104B4401 |

| 8” ANSI Cl.300 | 395 / 15.55 | 41,3 / 1.63 | 107,0 / 235.9 | M8106B4401 |

Other material on request.

Available with ACME for assembling direct on existing connections.

|

Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| ¾” BSP | 69 / 2.72 | 50 / 1.97 | 0,7 / 1.5 |

L101A4401A |

|

¾” NPT |

74 / 2.91 |

50 / 1.97 |

0,8 / 1.8 |

L102A4401 |

| 1” BSP | 70 / 2.76 | 50 / 1.97 | 0,7 / 1.5 |

L103A4401A |

|

1” NPT |

77 / 3.03 |

50 / 1.97 |

0,8 / 1.8 |

L104A4401 |

| 1 ¼” BSP | 70 / 2.76 | 50 / 1.97 | 0,7 / 1.5 |

L105A4401A |

|

1 ¼” NPT |

78 / 3.07 |

50 / 1.97 |

0,8 / 1.8 |

L106A4401 |

Other flange and material on request.

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

|

¾” ANSI Cl. 300 |

70 / 2.76 | 15,9 / 0.63 | 1,3 / 2.9 | L150A4401 |

| DN25 PN25/40 | 73 / 2.87 | 18,0 / 0.71 | 1,4 / 3.1 | L124A4401 |

| 1” ANSI Cl. 300 | 72 / 2.83 | 17,5 / 0.69 |

1,5 / 3.3 |

L152A4401 |

| DN32 PN25/40 | 73 / 2.87 | 18,0 / 0.71 | 1,5 / 3.3 | L126A4401 |

| 1 ¼” ANSI Cl. 300 | 74 / 2.91 | 19,0 / 0.75 | 1,5 / 3.3 |

L154A4401 |

Other material on request.

Available with ACME for assembling direct on existing connections.

|

Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| 1 ½” BSP | 99 / 3.90 | 65 / 2.56 | 1,5 / 3.3 |

L207A4401A |

|

1 ½” NPT |

102 / 4.02 |

65 / 2.56 |

1,6 / 3.5 |

L208A4401 |

| 2” BSP | 101 / 3.98 | 65 / 2.56 | 1,2 / 2.6 | L210A4401A |

|

2” NPT |

102 / 4.02 |

65 / 2.56 |

1,3 / 2.9 |

L211A4401 |

.jpg)

Other flange and material on request.

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN40 PN25/40 | 86,5 / 3.41 | 18 / 0.71 | 2,8 / 6.2 | L228A4401 |

| 1 ½” ANSI Cl. 300 | 88,5 / 3.41 | 20 / 0.79 |

3.2 / 7.1 |

L256A4401 |

| DN50 PN25/40 | 88,5 / 3.41 | 20 / 0.79 | 3.5 / 7.7 | L231A4401 |

| 2” ANSI Cl. 300 | 88,5 / 3.41 | 20 / 0.79 | 3.5 / 7.7 | L258A4401 |

Other material on request.

Available with ACME and Witworth threads (ie. W90) for assembling direct on existing connections.

| Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| 3” BSP | 134 / 5.28 | 100 / 3.94 | 3,0 / 6.6 | L414B4401A |

| 3” NPT | 144 / 5.67 | 100 / 3.94 | 3,0 / 6.6 | L415B4401 |

Other flange and material on request.

|

Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN65 PN25/40 | 112 / 4.41 | 15 (22)* / 0.59 (0.87)* |

5,0 / 11.0 |

L434B4401 |

| 2 ½” ANSI Cl. 300 | 112 / 4.41 | 15 (24)* / 0.59 (0.94)* | 5,0 / 11.0 | L460B4401 |

| DN80 PN25/40 | 112 / 4.41 | 15 (24)* / 0.59 (0.94)* |

5,5 / 12.1 |

L437B4401 |

| 3” ANSI Cl. 300 | 112 / 4.41 | 15 (24)* / 0.59 (0.94)* | 5,5 / 12.1 | L462B4401 |

Other material on request.

|

Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| 4” BSP | 156 / 6.14 | 125 / 4.92 | 6,1 / 13.4 |

L516B4401A |

|

4” NPT |

166 / 6.54 |

125 / 4.92 |

6,3 / 13.9 |

L517B4401 |

Other flange and material on request.

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN100 PN25/40 | 134 / 5.28 | 16 (24)* / 0.63 (0.94)* | 9,3 / 20.5 | L540B4401 |

| 4” ANSI Cl. 300 | 134 / 5.28 | 16 (24)* / 0.63 (0.94)* | 9,3 / 20.5 | L564B4401 |

Other material on request.

|

Thread |

Length mm/inch |

Head Width mm/inch |

Weight kg/lbs |

Code Nr. |

| 6” BSP | 201 / 7.91 | 190 / 7.48 | 17 / 37.5 |

L6110B4401A |

|

6” NPT |

207 / 8.15 |

190 / 7.48 |

17,3 / 38.1 |

L6111B4401 |

Other flange and material on request.

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN150 PN25/40 | 205 / 8.07 | 28 / 1.1 | 24,5 / 54.0 | L646B4401 |

| 6" ANSI Cl.300 | 213,5 / 8.41 | 36,5 / 1.44 | 31 / 68.3 | L6101B4401 |

Other flange and material on request.

| Connection |

Length mm/inch |

Thickness mm/inch |

Weight kg/lbs |

Code Nr. |

| DN200 PN25 | 223 / 8.78 | 30 / 1.18 | 47,5 / 104.7 | L8104A4401 |

| 8" ANSI Cl. 300 | 234 / 9.21 | 41,3 / 1.63 | 53 / 116.8 | L8106A4401 |

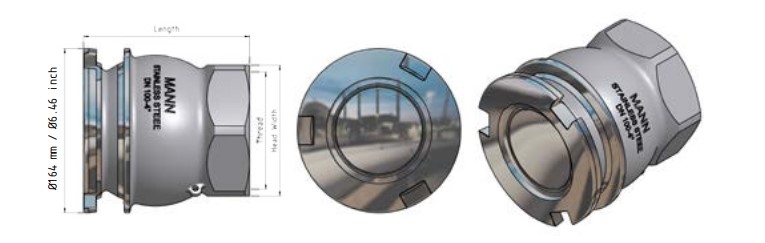

Dust Cap for Tank unit / Adapter

Dust protection in rubber

A Dust Cap gives very good protection against corrosion, and withstands both hot and cold environments.

Dust Cap for increased safety

It´s only possible to remove the cap from the Tank unit /Adapter after pulling the securing stift and at the same time twisting the cap. The Dust Cap is manually lockable with padlock.

Standard Caps in Composite. It covers the widest range of chemical and petroleum products.

.jpg)

| Size |

Code Nr. |

Material |

| 1" (Ø56mm) | CG100D2201 | Composite |

| 2" (Ø71mm) | C200D1300 |

Rubber |

| 3" (Ø119mm) | C400D1300 |

Rubber |

| 3" (Ø119mm) | C400A1101 | Aluminium |

| 3" (Ø119mm) | C400E2202 | Composite |

| 3" (Ø119mm) | C400C4401 | Stainless Steel |

| 4" (Ø164mm) | C500B1101 | Aluminium |

|

Size |

Code Nr. |

Material |

| 4" (Ø164mm) | C500E2202 |

Composite |

| 4" (Ø164mm) | C500C4401 | Stainless Steel |

| 6" (Ø238mm) | C600A1101 |

Aluminium |

| 6" (Ø238mm) | C600A2202 |

Composite |

| 6" (Ø238mm) | C600A4401 | Stainless Steel |

| 8" (Ø272mm) | C800B1101 |

Aluminium |

| 8" (Ø272mm) | C800B4401 | Stainless Steel |

3rd closure (valve) on Rail tankers, Containers and Tank trucks

The pressure caps are allowed by ADR/RID regulations as 3rd closure on Rail tankers, Containers and

Tank trucks. Meaning that the Pressure Cap can be used instead of the traditional Ball Valves.

The Mann Tek Pressure Cap for Tank units / Adapters is designed to maximize operator safety and containment safety.

Features

• Pressure indicator

• Depressurization

• Customs / tamper seal feature

• Automatic locking

• Manually lockable (with padlock)

| Size | Code Nr. |

Material |

| 2" (Ø71mm) | RG200A4401 | Stainless Steel |

| 3" (Ø119mm) | RG400A4401 | Stainless Steel |

Use the Mann Tek Dust Plug to prevent ingress of dirt and water in the couplings. The material in the Dust Plug is composite.

Other material on request.

| Size | Code Nr. | Material |

| 1" (Ø56mm) | V100A2201 |

Composite |

| 2" (Ø71mm) | V200A2201 |

Composite |

| 3" (Ø119mm) | V400A2201 |

Composite |

| 4" (Ø164mm) | V500A2201 |

Composite |

| 6" (Ø238mm) | V600A2201 |

Composite |

| 8" (Ø272mm) | V800A2201 |

Composite |

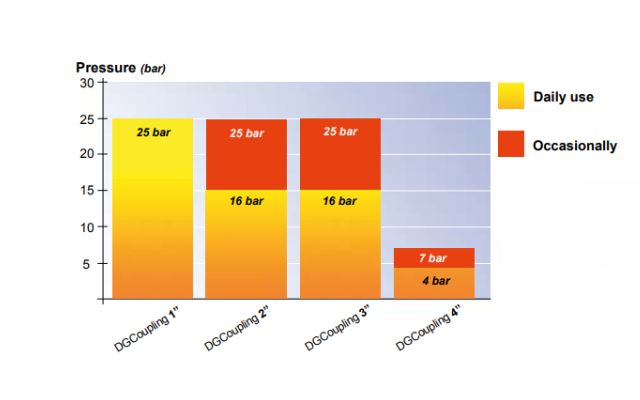

Connection / disconnection under pressure - maximum pressure

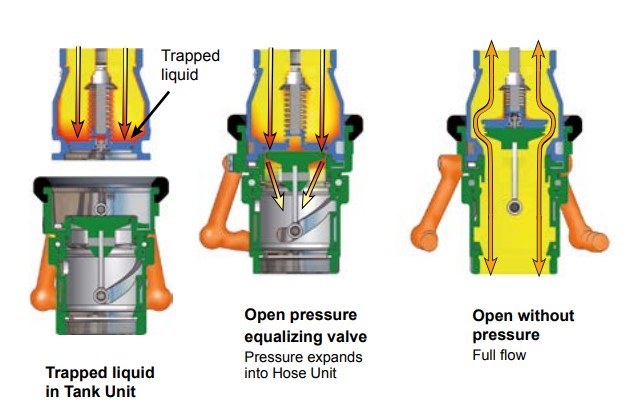

Use Pressure relief valve for Tank unit when higher pressure difference or trapped liquid.

This system dissipates trapped fluid pressure into hose coupler without spillage, to allow easy connection.

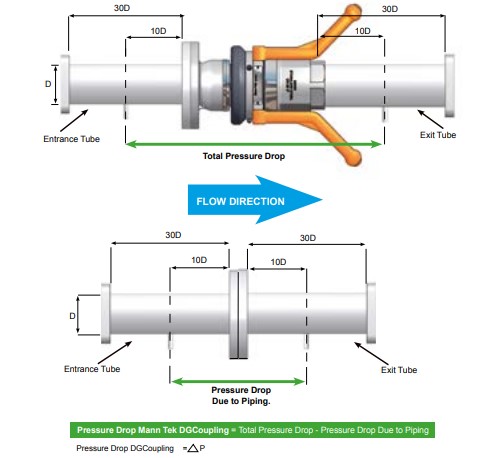

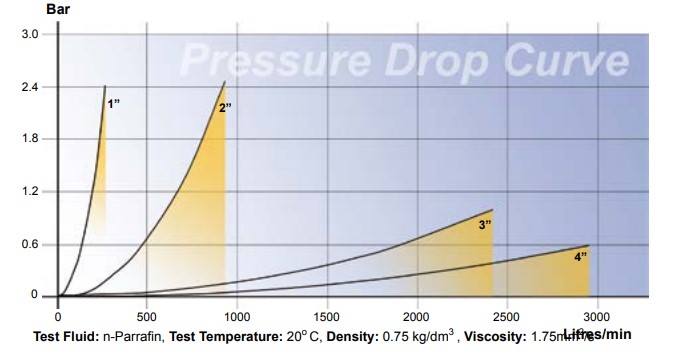

Illustration Pressure Drop Measurement

According to NATO STANAG 3756, Annex E

The Hose unit with "stop before disconnect" is a feature for detecting leakage in the Tank unit.

After stop and control for leakage the user must manually unlock the hose coupling before disconnection.

DGCouplings Tank units and Hose units are available with ACME and Witworth threads for assembling direct on excisting connections.

Open threaded ACME couplings has been used for a long time on the rail tank resulting in high product losses, environmental effects and health risks.

Tank units with no parts protruding from the coupling in connected position.

For mounting directly on ball-valves, etc.

On request!

Where there is a risk of excessive force on the hose due to unexpected movement between the loading and unloading station, combining the Dry Gas Coupling with a Safety Break Away coupling.

On request!

Technical Data

Size: 1” (Ø56 mm), 2” (Ø71 mm), 3” (Ø119 mm) , 4” (Ø164 mm) 6" (Ø238 mm) and 8" (Ø272 m)

Materials: Gunmetal / Brass and Stainless Steel 316L, SS-EN 10 272-1.4

Seal: Standard material: FPM (Viton) or NBR (Nitrile) according to EN549 B2

On request: EPDM, Kalrez, NBR Low temp, Perfluorelastomer (FFPM), Fluorsilicone rubber (MFQ), Chemraz and Viton GF.

Temperature range: -20ºC (-4ºF ) to 80ºC (176ºF) (larger temperature range from -50ºC (-58ºF ) up to +200ºC (392 ºF ) is possible, depending on Seal material)

Max Working Pressure: MWP 25 bar / MAWP 300 psi

Min. Burst Pressure: 125 bar / 1813 psi

Safety Factor: 5:1

End Connections: BSP- , NPT-, ACME- and Witworth threads, DIN- and ASAflanges. Other connections on request.

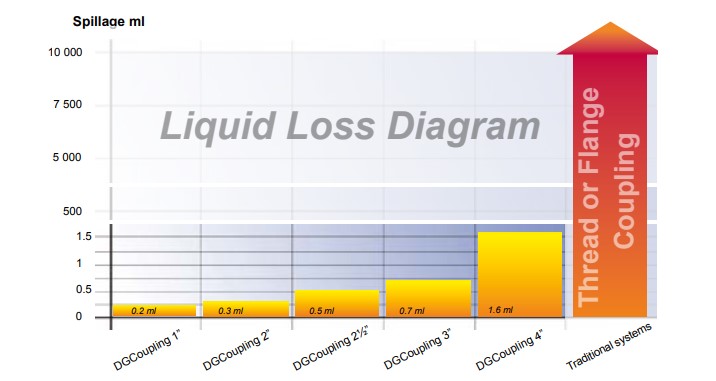

Comparasion of liquid loss during disconnection for Dry Gas Couplings and traditional systems using open threaded couplings, or flange to flange connections. The diagram shows that liquid loss for traditional systems may be as much as 10.000 times more than when using Dry Gas Couplings.

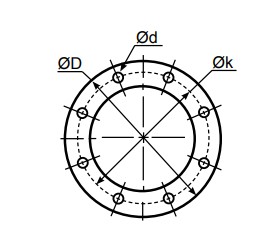

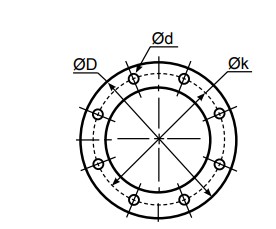

Flange Measurement - 1/2

Ø D = Diameter

Ø k = Centre diameter

n = Numer of holes

Ø d = Hole diameter

|

ANSI (ASA) B 16,5 |

|

INCH |

150 psi |

300 psi |

||||||

|

ØD |

Øk |

n |

Ød |

ØD |

Øk |

n |

Ød |

|

|

3/4” |

mm |

98,4 |

69,8 |

4 |

15,9 |

117,5 |

82,5 |

4 |

19 |

|

inch |

3 7/8 |

2 3/4 |

5/8 |

4 5/8 |

3 1/4 |

3/4 |

|||

|

1” |

mm |

107,7 |

79,4 |

4 |

15,9 |

123,8 |

88,9 |

4 |

19 |

|

inch |

4 1/4 |

3 1/8 |

5/8 |

4 7/8 |

3½ |

3/4 |

|||

|

1 1/4” |

mm |

117,5 |

88,9 |

4 |

15,9 |

133,3 |

98,4 |

4 |

19 |

|

inch |

4 5/8 |

3½ |

5/8 |

5 1/4 |

3 7/8 |

3/4 |

|||

|

1 1/2” |

mm |

127 |

98,4 |

4 |

15,9 |

155,6 |

114,3 |

4 |

22,2 |

|

inch |

5 |

3 7/8 |

5/8 |

6 1/8 |

4½ |

7/8 |

|||

|

2” |

mm |

152,4 |

120,6 |

4 |

19 |

165,1 |

127 |

8 |

19 |

|

inch |

6 |

4 3/4 |

3/4 |

6½ |

5 |

3/4 |

|||

|

2 1/2” |

mm |

177,8 |

139,7 |

4 |

19 |

190,5 |

149,2 |

8 |

22,2 |

|

inch |

7 |

5½ |

3/4 |

7½ |

5 7/8 |

7/8 |

|||

|

3” |

mm |

190,5 |

152,4 |

4 |

19 |

209,5 |

168,3 |

8 |

22,2 |

|

inch |

7½ |

6 |

3/4 |

8 1/4 |

6 5/8 |

7/8 |

|||

|

4” |

mm |

228,5 |

190,5 |

8 |

19 |

254 |

200 |

8 |

22,2 |

|

inch |

9 |

7½ |

3/4 |

10 |

7 7/8 |

7/8 |

|||

|

5” |

mm |

254 |

215,9 |

8 |

22,2 |

279,4 |

234,9 |

8 |

22,2 |

|

inch |

10 |

8½ |

7/8 |

11 |

9 1/4 |

7/8 |

|||

|

6” |

mm |

279,4 |

241,3 |

8 |

22,2 |

317,5 |

269,9 |

12 |

22,2 |

|

inch |

11 |

9½ |

7/8 |

12½ |

10 5/8 |

7/8 |

|||

|

8” |

mm |

342,9 |

298,4 |

8 |

22,2 |

381 |

330,2 |

12 |

25,4 |

|

inch |

13½ |

11 3/4 |

7/8 |

15 |

13 |

1 |

|||

|

10” |

mm |

406,4 |

361,9 |

12 |

25,4 |

444,5 |

387,3 |

16 |

28,6 |

|

inch |

16 |

141/4 |

1 |

17½ |

15 1/4 |

1 1/8 |

|||

|

12” |

mm |

482,6 |

431,8 |

12 |

25,4 |

520,7 |

450,8 |

16 |

31,7 |

|

inch |

19 |

17 |

1 |

20½ |

17 3/4 |

1 1/4 |

|

TW DIN 28459 |

|

|

DN |

ØD |

Øk |

n |

Ød |

|

TW1 |

50 |

mm |

154 |

130 |

8 |

11 |

|

inch |

6.06 |

5.12 |

|

0.43 |

||

|

TW1 |

80 |

mm |

154 |

130 |

8 |

11 |

|

inch |

6.06 |

5.12 |

|

0.43 |

||

|

TW3 |

100 |

mm |

174 |

150 |

8 |

14 |

|

inch |

6.85 |

5.91 |

|

0.55 |

||

|

TW5 |

125 |

mm |

204 |

176 |

8 |

14 |

|

inch |

8.03 |

6.93 |

|

0.55 |

||

|

TW7 |

150 |

mm |

240 |

210 |

12 |

14 |

|

inch |

9.45 |

8.27 |

|

0.55 |

|

T.T.M.A |

|

INCH |

ØD |

Øk |

n |

Ød |

|

2” |

mm |

114,3 |

95,3 |

6 |

11,1 |

|

inch |

4.50 |

3.75 |

0.44 |

||

|

3” |

mm |

142,9 |

123,8 |

8 |

11,1 |

|

inch |

5.63 |

4.87 |

0.44 |

||

|

4” |

mm |

168,3 |

149,2 |

8 |

11,1 |

|

inch |

6.63 |

5.87 |

0.44 |

||

|

5” |

mm |

196,9 |

177,8 |

12 |

11,1 |

|

inch |

7.75 |

7.00 |

0.44 |

||

|

6” |

mm |

228,6 |

206,4 |

12 |

11,1 |

|

inch |

9.00 |

8.13 |

0.44 |

||

|

8” |

mm |

276,2 |

257,2 |

16 |

11,1 |

|

inch |

10.87 |

10.13 |

0.44 |

Flange Measurement - 2/2

Ø D = Diameter

Ø k = Centre diameter

n = Numer of holes

Ø d = Hole diameter

|

ANSI (ASA) B 16,5 |

|

INCH |

150 psi |

300 psi |

||||||

|

ØD |

Øk |

n |

Ød |

ØD |

Øk |

n |

Ød |

|

|

3/4” |

mm |

98,4 |

69,8 |

4 |

15,9 |

117,5 |

82,5 |

4 |

19 |

|

inch |

3 7/8 |

2 3/4 |

5/8 |

4 5/8 |

3 1/4 |

3/4 |

|||

|

1” |

mm |

107,7 |

79,4 |

4 |

15,9 |

123,8 |

88,9 |

4 |

19 |

|

inch |

4 1/4 |

3 1/8 |

5/8 |

4 7/8 |

3½ |

3/4 |

|||

|

1 1/4” |

mm |

117,5 |

88,9 |

4 |

15,9 |

133,3 |

98,4 |

4 |

19 |

|

inch |

4 5/8 |

3½ |

5/8 |

5 1/4 |

3 7/8 |

3/4 |

|||

|

1 1/2” |

mm |

127 |

98,4 |

4 |

15,9 |

155,6 |

114,3 |

4 |

22,2 |

|

inch |

5 |

3 7/8 |

5/8 |

6 1/8 |

4½ |

7/8 |

|||

|

2” |

mm |

152,4 |

120,6 |

4 |

19 |

165,1 |

127 |

8 |

19 |

|

inch |

6 |

4 3/4 |

3/4 |

6½ |

5 |

3/4 |

|||

|

2 1/2” |

mm |

177,8 |

139,7 |

4 |

19 |

190,5 |

149,2 |

8 |

22,2 |

|

inch |

7 |

5½ |

3/4 |

7½ |

5 7/8 |

7/8 |

|||

|

3” |

mm |

190,5 |

152,4 |

4 |

19 |

209,5 |

168,3 |

8 |

22,2 |

|

inch |

7½ |

6 |

3/4 |

8 1/4 |

6 5/8 |

7/8 |

|||

|

4” |

mm |

228,5 |

190,5 |

8 |

19 |

254 |

200 |

8 |

22,2 |

|

inch |

9 |

7½ |

3/4 |

10 |

7 7/8 |

7/8 |

|||

|

5” |

mm |

254 |

215,9 |

8 |

22,2 |

279,4 |

234,9 |

8 |

22,2 |

|

inch |

10 |

8½ |

7/8 |

11 |

9 1/4 |

7/8 |

|||

|

6” |

mm |

279,4 |

241,3 |

8 |

22,2 |

317,5 |

269,9 |

12 |

22,2 |

|

inch |

11 |

9½ |

7/8 |

12½ |

10 5/8 |

7/8 |

|||

|

8” |

mm |

342,9 |

298,4 |

8 |

22,2 |

381 |

330,2 |

12 |

25,4 |

|

inch |

13½ |

11 3/4 |

7/8 |

15 |

13 |

1 |

|||

|

10” |

mm |

406,4 |

361,9 |

12 |

25,4 |

444,5 |

387,3 |

16 |

28,6 |

|

inch |

16 |

141/4 |

1 |

17½ |

15 1/4 |

1 1/8 |

|||

|

12” |

mm |

482,6 |

431,8 |

12 |

25,4 |

520,7 |

450,8 |

16 |

31,7 |

|

inch |

19 |

17 |

1 |

20½ |

17 3/4 |

1 1/4 |

|

TW DIN 28459 |

|

|

DN |

ØD |

Øk |

n |

Ød |

|

TW1 |

50 |

mm |

154 |

130 |

8 |

11 |

|

inch |

6.06 |

5.12 |

|

0.43 |

||

|

TW1 |

80 |

mm |

154 |

130 |

8 |

11 |

|

inch |

6.06 |

5.12 |

|

0.43 |

||

|

TW3 |

100 |

mm |

174 |

150 |

8 |

14 |

|

inch |

6.85 |

5.91 |

|

0.55 |

||

|

TW5 |

125 |

mm |

204 |

176 |

8 |

14 |

|

inch |

8.03 |

6.93 |

|

0.55 |

||

|

TW7 |

150 |

mm |

240 |

210 |

12 |

14 |

|

inch |

9.45 |

8.27 |

|

0.55 |

|

T.T.M.A |

|

INCH |

ØD |

Øk |

n |

Ød |

|

|

2” |

mm |

114,3 |

95,3 |

6 |

11,1 |

|

inch |

4.50 |

3.75 |

0.44 |

||

|

3” |

mm |

142,9 |

123,8 |

8 |

11,1 |

|

inch |

5.63 |

4.87 |

0.44 |

||

|

4” |

mm |

168,3 |

149,2 |

8 |

11,1 |

|

inch |

6.63 |

5.87 |

0.44 |

||

|

5” |

mm |

196,9 |

177,8 |

12 |

11,1 |

|

inch |

7.75 |

7.00 |

0.44 |

||

|

6” |

mm |

228,6 |

206,4 |

12 |

11,1 |

|

inch |

9.00 |

8.13 |

0.44 |

||

|

8” |

mm |

276,2 |

257,2 |

16 |

11,1 |

|

inch |

10.87 |

10.13 |

0.44 |

||

Didn't find the right Dry Gas Couplings?

Fill in the form below, and we'll assist you further!

Curious about our blog? Check out all our items here!

Contact us here