Safety Break-away Couplings

Safety Break-away couplings are used to prevent pull away accidents, protect terminal and loading/unloading equipment and eliminated unwanted product release.

The break-away couplings has a diverted breaking point which will break at a determined break-load where upon the internal valves will automatically close on both sides.

This will in a longer time frame minimize down time, save money, equipment and the environment.

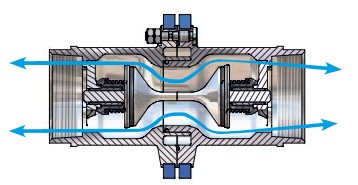

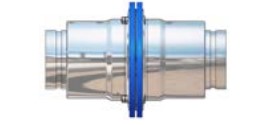

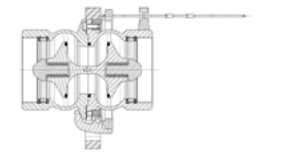

SBCoupling before emergency disconnect

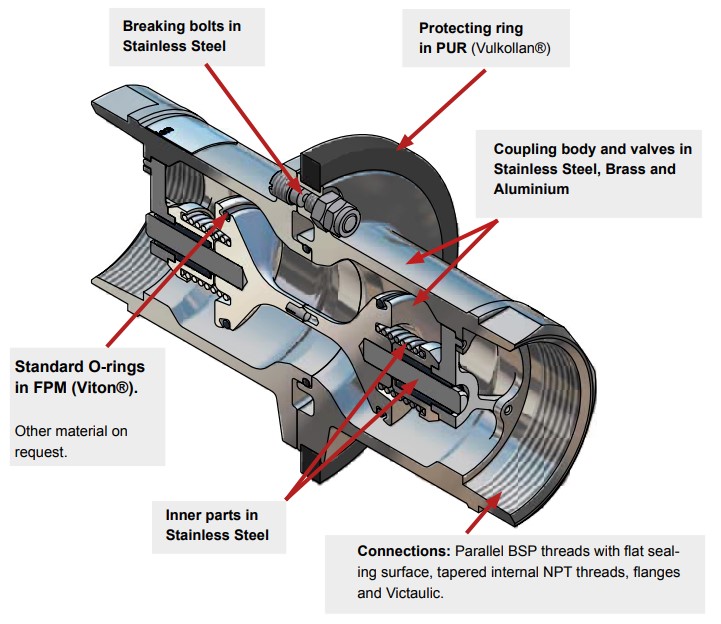

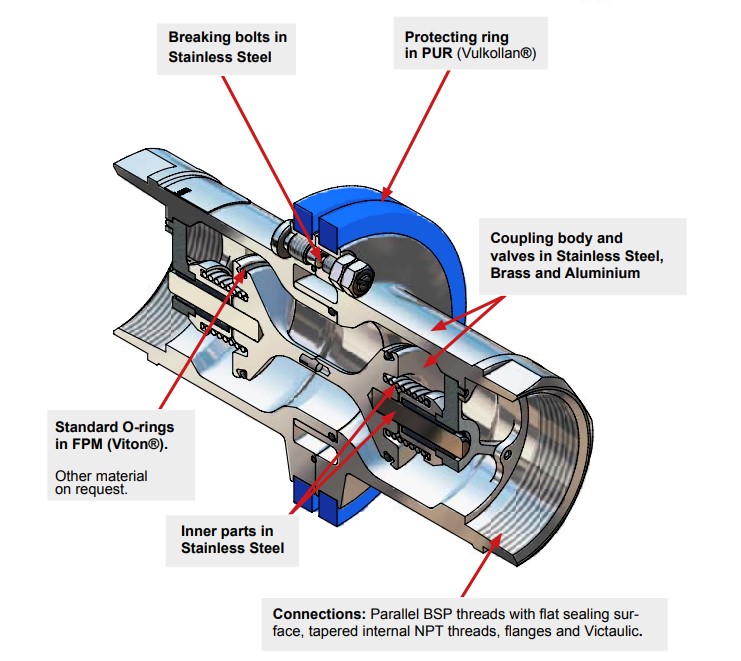

The safety break-away valve consists of two halves, each with a valve that has a o-ring seal.

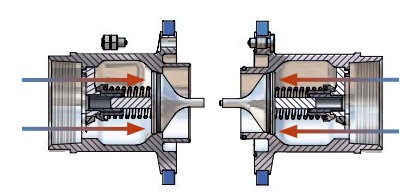

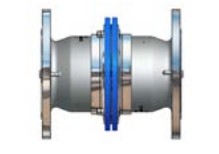

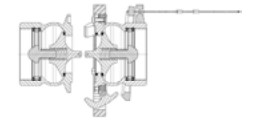

SBCoupling after emergency disconnect

When the SBCouplings separate, it allows the valves to close. The two valves closes rapidly, minimizing exposure to personnel and the environment.

The SBCouplings, Safety breakaway couplings has three external break bolts. In the case of axial tension all of the bolts take up the force

corresponding to the break force on the hose with a safety margin.

Non-axial forces concentrate the tension forces more strongly on one bolt, so that the safety break-away coupling reacts in a natural way

to the reduction of the hose break forces.

Features and Applications

Features

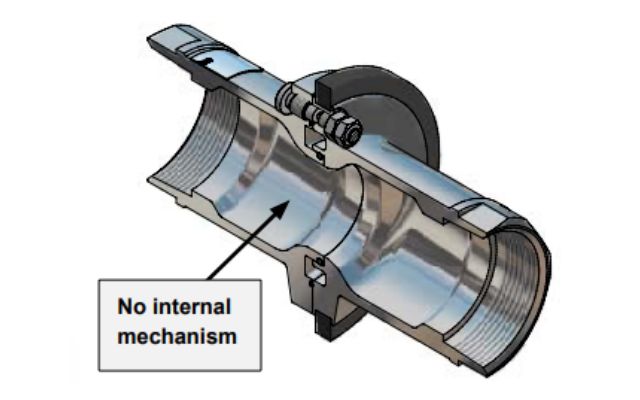

• Passive security against situations

where a hose or loading arm could be

subjected to inadvertent excessive loads.

• Design features are a simple mechanism

and no loose components which could be

lost after release.

• Operates independently of shut off safety

system and does not require an external

power source.

• Easy to reset on site with one person

• High flowrate / low pressure drop

• Very low loss, positive shut-off of both

coupling halves results in minimum

product loss.

• Lightweight and robust design.

• Available with ANSI/DIN flanges or

threaded (BSP or NPT

Applications

Liquified gases

LPG, Butane, Propane and Blends.

Co2, DME, LNG

Chemicals and Hydrocarbons

Aromatics, Ethylenes and Propylenes,

VCM, Alcohols and Acids, Diesel, Jet A1.

Refrigerants Forane.

Oil and Petrochemical

Bulk Loading/Unloading, Road Tankers

Rail Tankers, Process Product Transfer

Tank Cleaning

Marine and Offshore

Ship to Rig Fluid Transfer

Ship to Shore Fluid Transfer

Ship to Ship Fluid Transfer

Bunkering, Marine Refuelling

Speciality

Hydraulic Oils, Inks, Paints, Solvents,

Locomotive Fuelling, Helicopter Fuelling,

Food processing industry

Plant engineering and construction

Power plant construction, Food processing industry

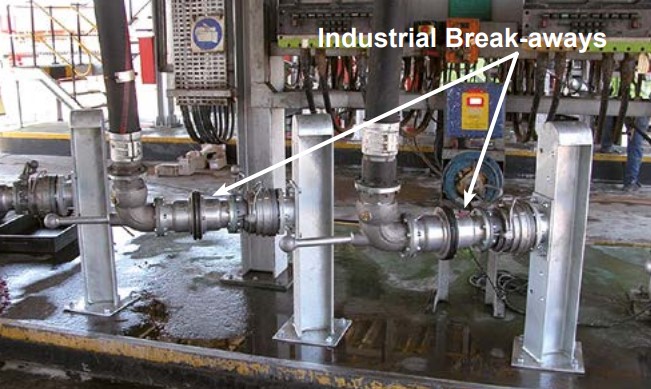

Industrial Break-away

Typically installed into loading arm and hose assemblies, where at least one side of the coupling is attached to a rig and fixed point.

Release with a tensile force being applied at an angle to the plane of the coupling housing, up to 90 degrees.

Marine Break-away

Marine Safety Break-aways are designed to only release by inline pull and used between two strings of hose.

Release by inline pull only.

Industrial Break-away coupling is utilized all industrial product transfer installations.

The industrial SBCouplings are specifically designed to be able to activate with a tensile force being applied at an angle to the plane of the coupling housing, up to 90 degrees.

Examples of Connection combinations

BSP Female thread / BSP Female thread

Male thread / Male thread

Victaulic / Victaulic

Flange / Flange

NPT Female thread / NPT Female thread

NPT Female thread / NPT Male thread

also available with BSP

NPT Female thread / Victaulic

Flange / Thread

(BSP/NPT -Female/Male and Victaulic)

Other combinations of connections on request.

Technical data - Sizes, connections, materials and seals

Coupling sizes and connections

| Nominal width | Breaking force1) | Connection2) | kg (Stainless) | kg (Aluminium) | ||||||

| SS | Alu | |||||||||

| 1" | 4,8 kN | 3,2 kN | 1" Thread | 1,6 | - | |||||

| 1" Flange | 2,7 | - | ||||||||

| 2" | 13 kN | 9 kN | 2" Thread | 2,6 | 0,9 | |||||

| 2" Flange | 7,3 | 2,5 | ||||||||

| 2½" | 22 kN | 10 kN | 2½" Thread | 7,4 | 2,5 | |||||

| 2½" Flange | 13,2 | 4,5 | ||||||||

| 3" | 33 kN | 15 kN | 3" Thread | 8,5 | 2,9 | |||||

| 3" Flange | 15,1 | 5,1 | ||||||||

| 4" | 52 kN | 24 kN | 4" Thread | 15,5 | 5,3 | |||||

| 4" Flange | 20,7 | 7,0 | ||||||||

| 5" | 81 kN | 37 kN | 5" Thread | 32,0 | 12,0 | |||||

| 5" Victaulic | 31,0 | 11,7 | ||||||||

| 6" | 92 kN | 54 kN | 6" Thread | 46,8 | 15,9 | |||||

| 6" Flange | 57,6 | 19,6 | ||||||||

| 8" | 165 kN | 96 kN | 8" Thread | - | - | |||||

| 8" Flange | 71,0 | 25,9 | ||||||||

| 10" | 151 kN | 151 kN | 10" Flange | 120 | - | |||||

| 12" | 217 kN | 217 kN | 12" Flange | 185 | - | |||||

1) Mann Tek Standard. Other on request.

2) Threads: Female and Male (F/F - F/M - M/M) BSP, Female and Male (F/F - F/M - M/M) NPT

Flanges: ANSI 150 psi / ANSI 300 psi, DN 25-150 PN 10/16 and PN 25/40, TW1/50, TW3/80, TW7/150, T.T.M.A .

Others: Victaulic

| Component | Material | Standard | Operation temperature3) | ||||||||

| Housing Check valve | SS (Stainless Steel) | EN 10272 - 1.4404+AT | -40oC to 250oC | ||||||||

| EN 10213 - 1.4409+AT | |||||||||||

| Br/Gm (Brass/Gun metal) | EN 12164 - CW614N | -40oC to 200oC | |||||||||

| EN 1982 - CB491K-GS | |||||||||||

| AL (Aluminium) | EN 755 - AW-6262-T6 | -40oC to 150oC | |||||||||

| EN 1706 -AC-42100-T6 | |||||||||||

| Component | Material | Description4) | Operation temperature3) | |||||||||

| O-ring | FKM | Viton™ | -30oC to 200oC | |||||||||

| EPDM | Buna AP | -40oC to 120oC | ||||||||||

| FFKM | Kalrez™ Chemraz™ | -15oC to 230oC | ||||||||||

| NBR | Perbunan | -38oC to 80oC | ||||||||||

| Working pressure: 16 bar / 25 bar 150psi / 300 psi 40 bar / 600 psi on request. | ||||||||||||

Working pressure: 16 bar / 25 bar 150psi / 300 psi 40 bar / 600 psi on request

3) For temperature stability of the seal material used must be considered separately for each individual case

4) Kalrez, Viton = Registered Trademarks of DuPont; Chemraz = Registered Trademark of Green Tweed

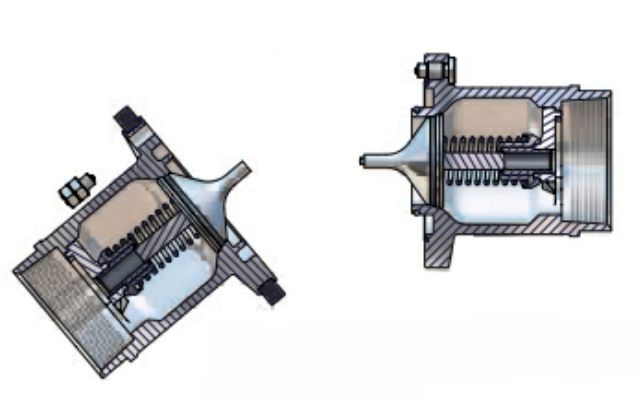

Marine version of SBCouplings are designed specifically to be installed within a hose string, where the coupling would have a length of hose attached to both sides.

This coupling incorporates the same internal mechanism as our Industrial couplings, but has additional external features that provide increased resistance to torsional and bending moment forces which may be applied to the coupling, preventing premature activation in the unpredictable marine environment.

Typical applications include ship to offshore platform, and ship to ship product transfer opertations.

Examples of Connection combinations

Other combinations of connections on request

BSP Female thread / BSP Female thread

Male thread / Male thread

Victaulic / Victaulic

Flange / Flange

NPT Female thread / NPT Female thread

NPT Female thread / NPT Male thread

also available with BSP

NPT Female thread / Victaulic

Flange / Thread

(BSP/NPT -Female/Male and Victaulic)

Coupling sizes and connections

| Nominal width | Breaking force1) | Connection2) | kg (Stainless) | kg (Aluminium) | ||||||

| SS | Alu | |||||||||

| 1" | 4,8 kN | 3,2 kN | 1" Thread | 1,6 | - | |||||

| 1" Flange | 2,7 | - | ||||||||

| 2" | 13 kN | 9 kN | 2" Thread | 2,6 | 0,9 | |||||

| 2" Flange | 7,3 | 2,5 | ||||||||

| 2½" | 22 kN | 10 kN | 2½" Thread | 7,4 | 2,5 | |||||

| 2½" Flange | 13,2 | 4,5 | ||||||||

| 3" | 33 kN | 15 kN | 3" Thread | 8,5 | 2,9 | |||||

| 3" Flange | 15,1 | 5,1 | ||||||||

| 4" | 52 kN | 24 kN | 4" Thread | 15,5 | 5,3 | |||||

| 4" Flange | 20,7 | 7,0 | ||||||||

| 5" | 81 kN | 37 kN | 5" Thread | 32,0 | 12,0 | |||||

| 5" Victaulic | 31,0 | 11,7 | ||||||||

| 6" | 92 kN | 54 kN | 6" Thread | 46,8 | 15,9 | |||||

| 6" Flange | 57,6 | 19,6 | ||||||||

| 8" | 165 kN | 96 kN | 8" Thread | - | - | |||||

| 8" Flange | 71,0 | 25,9 | ||||||||

| 10" | 151 kN | 151 kN | 10" Flange | 120 | - | |||||

| 12" | 217 kN | 217 kN | 12" Flange | 185 | - | |||||

1) Mann Tek Standard. Other on request.

2) Threads: Female and Male (F/F - F/M - M/M) BSP, Female and Male (F/F - F/M - M/M) NPT

Flanges: ANSI 150 psi / ANSI 300 psi, DN 25-150 PN 10/16 and PN 25/40, TW1/50, TW3/80, TW7/150, T.T.M.A .

Others: Victaulic

| Component | Material | Standard | Operation temperature3) | ||||||||

| Housing Check valve | SS (Stainless Steel) | EN 10272 - 1.4404+AT | -40oC to 250oC | ||||||||

| EN 10213 - 1.4409+AT | |||||||||||

| Br/Gm (Brass/Gun metal) | EN 12164 - CW614N | -40oC to 200oC | |||||||||

| EN 1982 - CB491K-GS | |||||||||||

| AL (Aluminium) | EN 755 - AW-6262-T6 | -40oC to 150oC | |||||||||

| EN 1706 -AC-42100-T6 | |||||||||||

| Component | Material | Description4) | Operation temperature3) | |||||||||

| O-ring | FKM | Viton™ | -30oC to 200oC | |||||||||

| EPDM | Buna AP | -40oC to 120oC | ||||||||||

| FFKM | Kalrez™ Chemraz™ | -15oC to 230oC | ||||||||||

| NBR | Perbunan | -38oC to 80oC | ||||||||||

| Working pressure: 16 bar / 25 bar 150psi / 300 psi 40 bar / 600 psi on request. | ||||||||||||

Working pressure: 16 bar / 25 bar 150psi / 300 psi 40 bar / 600 psi on request.

3) For temperature stability of the seal material used must be considered separately for each individual case

4) Kalrez, Viton = Registered Trademarks of DuPont; Chemraz = Registered Trademark of Green Tweed

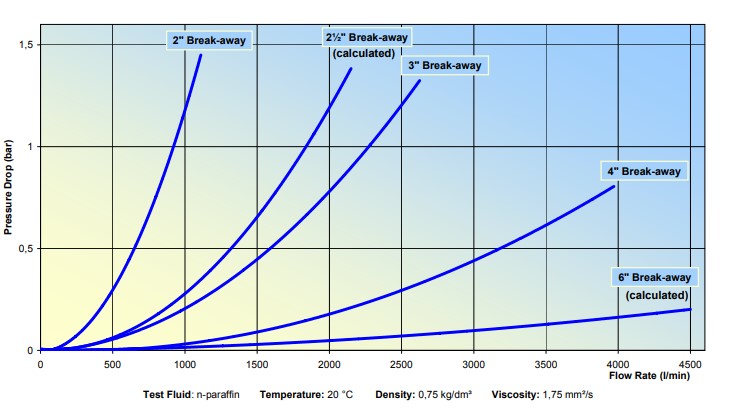

Flow Diagram (Pressure Drop) for Industrial and Marine Break-away couplings

Industrial or Marine Break Away

- Non Closure

Where there is a risk of excessive force on the hose due to unexpected movement between the loading and unloading station, combining the Dry Disconnect Coupling or Swivel with a Safety Break Away coupling.

Hose Swivel with Breakaway integrated

Hose Swivel with Breakaway integrated

Dry Gas coupling Hose unit with Break-away integrated

Dry disconnect coupling Hose unit with Break-away integrated

General info

For safe transfer of all your hazardous and non-hazardous products.

The Break-away Cable release series, is designed specifically to minimize spillage and damage associated with drive away and pull away incidents.

The Coupling automatically senses an excessive load, closes its valves and then permits disconnection.

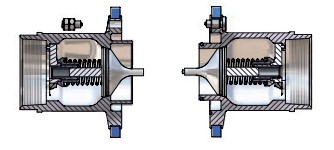

The safety break-away valve consists of two halves, each with a valve that has a flat type-sealing surface similar to a dry disconnect coupling. The valve remains constantly open under normal use.

The two halves of the break-away coupling only close when there is excessive force, such as in a Road Tanker, or Rail Car drive away situation.

The release is executed by pulling out the locking bolts with the help of the cable. The locking bolts hold the two pressure clamps in position which press both casing halves of the SBCoupling together. A guiding pin set in between serves the alignment of the locking bolts.

When the SBCouplings separate, this allows the poppets to close. Product loss is minimized because of the two poppets close rapidly, minimizing exposure to personnel and the environment.

SBCouplings before emergency disconnect.

SBCouplings after emergency disconnect.

• Passive security against situations where

a hose or loading arm could be subjected

to inadvertent excessive loads.

• Minimal Tension forces on the cable are

required to release the SBCouplings-

system.

• Design features are a simple mechanism

and no loose components which could be

lost after release.

• Operates independently of shut off safety

system and does not require an external

pow

Didn't find the right Safety Break-away Couplings?

Fill in the form below, and we'll assist you further!

Curious about our blog? Check out all our items here!

Contact us here