A Triclamp coupling is a hygienic coupling, making it particularly suitable as a sanitary connection in the food and pharmaceutical industries. Worldwide, many food manufacturers use these type of couplings. Due to their ease of handling, minimal components, and robustness, these couplings are popular among companies requiring hygienic connections between their systems. Triclamp couplings provide excellent sealing and are easy to install and maintain. Made from stainless steel 304 and 316, these couplings are designed for long durability and corrosion resistance, which is crucial in environments where hygiene is the top priority. The simple design of the couplings allows them to be secured with sturdy clamps, ensuring a reliable, leak-free connection essential for your production processes.

There are several reasons to opt for a Triclamp coupling. Firstly, as mentioned, they are easy to connect and disconnect, which saves significant time. This reduces downtime in your production process and lowers operational costs. Additionally, Triclamp couplings are designed with hygiene in mind. Their simple design, free of edges and corners, makes them easy to clean. Thorough cleaning helps maintain high hygiene standards and prevents cross-contamination of end products. Moreover, the couplings are versatile and can be used in various applications in dairy production, such as milk transport, pasteurization, and packaging. This versatility makes the Tri-Clamp coupling an indispensable tool for every manufacturer in the dairy industry.

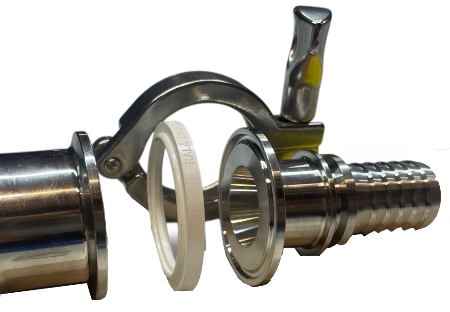

A Triclamp coupling consists of two flanges with a Triclamp seal between them. The flanges are pressed together with a clamp band, also known as a Triclamp clamp. These clamps are available in different strengths: light, medium, and heavy. Depending on the diameter and pressure of the system, you select the appropriate clamp. Having trouble choosing? Feel free to ask us.

When purchasing components for your Tri-clamp installation, it’s important to know that Tri-clamp couplings are available in three size standards. The most commonly used standard is the DIN size. However, this is not always the standard. When buying Tri-clamp components, pay attention to the flange size (outer flange diameter) and the inner diameter of the flange (the flow opening).

Tri-clamp couplings are available in various sizes, namely DN, ISO, and Inch. The most commonly used Triclamp sizes in Europe are:

| DN | Inner Pipe Diameter | Outer Pipe Diameter | Flange Size |

| DN15 | 16mm | 19mm | 34mm |

| DN20 | 20mm | 23mm | 34mm |

| DN25 | 26mm | 29mm | 50.5mm |

| DN32 | 32mm | 35mm | 50.5mm |

| DN40 | 38mm | 41mm | 50.5mm |

| DN50 | 50mm | 53mm | 64mm |

| DN65 | 66mm | 70mm | 91mm |

| DN80 | 81mm | 85mm | 106mm |

Overview of Commonly Used Tri-clamp Ferrules

<

| DIN 32676 Series 2 | DIN 32676 Table C | |||||||

| Nominal | A x WT | C | C* | Nominal | A x WT | C | ||

| DN10 | 13.0 x 1.5 | 34mm | 1/4" | 6.35 x 0.89 | 25.0mm | |||

| DN15 | 19.0 x 1.5 | 34mm | 3/8" | 9.53 x 0.89 | 25.0mm | |||

| DN20 | 23.0 x 1.5 | 34mm | 1/2" | 12.7 x 1.65 | 25.0mm | |||

| DN25 | 29.0 x 1.5 | 50.5mm | 3/4" | 19.05 x 1.65 | 25.0mm | |||

| DN32 | 35.0 x 1.5 | 50.5mm | 1" | 25.4 x 1.65 | 50.5mm | |||

| DN40 | 41.0 x 1.5 | 50.5mm | 1.1/2" | 38.1 x 1.65 | 50.5mm | |||

| DN50 | 53.0 x 1.5 | 64.0mm | 2" | 50.8 x 1.65 | 64.0mm | |||

| DN65 | 70.0 x 2.0 | 91.0mm | 2.1/2" | 63.5 x 1.65 | 77.5mm | |||

| DN80 | 85.0 x 2.0 | 106.0mm | 3" | 76.1 x 1.65 | 91.0mm | |||

| DN100 | 104.0 x 2.0 | 119.0mm | 4" | 101.6 x 2.11 | 119.0mm | |||

| DN125 | 129.0 x 2.0 | 155.0mm | 144.4mm | 6" | 152.4 x 2.77 | 167.0mm | ||

| DN150 | 154.0 x 2.0 | 183.0mm | 167.0mm | |||||

| DN200 | 204.0 x 2.0 | 233.5mm | 217.4mm | BS 4825-3 | ||||

| DN250* | 254.0 x 2.0 | 268.0mm | Nominal | A x WT | C | |||

| DN300* | 304.0 x 2.0 | 319.0mm | 1/2" | 12.7 x 1.6 | 25.4mm | |||

| 3/4" | 19.05 x 1.6 | 25.4mm | ||||||

| 1" | 25.65 x 1.73 | 50.5mm | ||||||

| ISO 1127 | 1.1/2" | 38.35 x 1.73 | 50.5mm | |||||

| Nominal | A x WT | C | C* | C* | 2" | 51.05 x 1.73 | 64.0mm | |

| DN8 | 13.5 x 1.6 | 25.4mm | 34.0mm | 50.5mm | 2.1/2" | 63.75 x 1.73 | 77.5mm | |

| DN10 | 17.2 x 1.6 | 25.4mm | 34.0mm | 50.5mm | 3" | 76.45 x 1.73 | 91.0mm | |

| DN15 | 21.3 x 1.6 | 50.5mm | 34.0mm | 50.5mm | 3.1/2" | 88.9 x 2.10 | 106.0mm | |

| DN20 | 26.9 x 1.6 | 50.5mm | 4" | 101.85 x 2.13 | 119.0mm | |||

| DN25 | 33.7 x 1.6* | 50.5mm | 4.1/2" | 114.95 x 2.33 | 130.0mm | |||

| DN25 | 33.7 x 2.0 | 50.5mm | 5" | 127.00 x 2.00 | 144.4mm | |||

| DN32 | 42.4 x 2.0 | 64.0mm | 50.5mm | 5.1/2" | 140.55 x 2.40 | 155.0mm | ||

| DN40 | 48.3 x 2.0 | 64.0mm | 6" | 154.0 x 2.00 | 167.0mm | |||

| DN50 | 60.3 x 2.0 | 77.5mm | 6.5/8" | 169.35 x 3.13 | 183.0mm | |||

| DN65 | 76.1 x 2.0 | 91.0mm | 8" | 204.0 x 2.00 | 217.4mm | |||

| DN80 | 88.9 x 2.3 | 106.0mm | 8.5/8" | 220.55 x 3.33 | 233.5mm | |||

| DN100 | 114.3 x 2.3 | 130.0mm | 10" | 254.0 x 2.00 | 268.0mm | |||

| DN125 | 139.7 x 2.6 | 155.0mm | 10.5/8" | 273.0 x 3.35 | 286.1mm | |||

| DN150 | 168.3 x 2.6 | 183.0mm | 12" | 304.8 x 2.00 | 319.0mm | |||

| 12.5/8" | 323.8 x 3.95 | 338.0mm | ||||||

| ASME BPE (Imperial) | ||||||||

| Nominal | A x WT | C | ||||||

| 1/4" | 6.35 | x | 0.89 | 20 Gauge | 25.4mm | |||

| 3/8" | 9.53 | x | 0.89 | 20 Gauge | 25.4mm | |||

| 3/8" | 9.53 | x | 1.22 | 18 Gauge | 25.4mm | |||

| 1/2" | 12.7 | x | 1.65 | 16 Gauge | 25.4mm | |||

| 3/4" | 19.05 | x | 1.65 | 16 Gauge | 25.4mm | |||

| 1" | 25.4 | x | 1.65 | 16 Gauge | 50.5mm | |||

| 1.1/2" | 38.1 | x | 1.65 | 16 Gauge | 50.5mm | |||

| 2" | 50.8 | x | 1.65 | 16 Gauge | 64.0mm | |||

| 2.1/2" | 63.5 | x | 1.65 | 16 Gauge | 77.5mm | |||

| 3" | 76.2 | x | 1.65 | 16 Gauge | 91.0mm | |||

| 4" | 101.6 | x | 2.11 | 14 Gauge | 119.0mm | |||

| 6" | 152.4 | x | 2.77 | 12 Gauge | 167.0mm | |||

Didn't find the right Tri Clamp Fittings DIN32676?

Fill in the form below, and we'll assist you further!

Curious about our blog? Check out all our items here!

Contact us here